Through their ability to catch every particle issuing from a grinding chamber without supervision, dosing chambers on espresso grinders have always offered potential waste-saving and multitasking benefits.

Yet dosing chambers often contribute to retention; they tend to pitch grinds to one side and miss the basket while dispensing; they can lead to even more waste if filled up with a grind that should have been adjusted; and the endless thwacking of the dosing chamber handle inevitably takes a toll on a barista’s wrist.

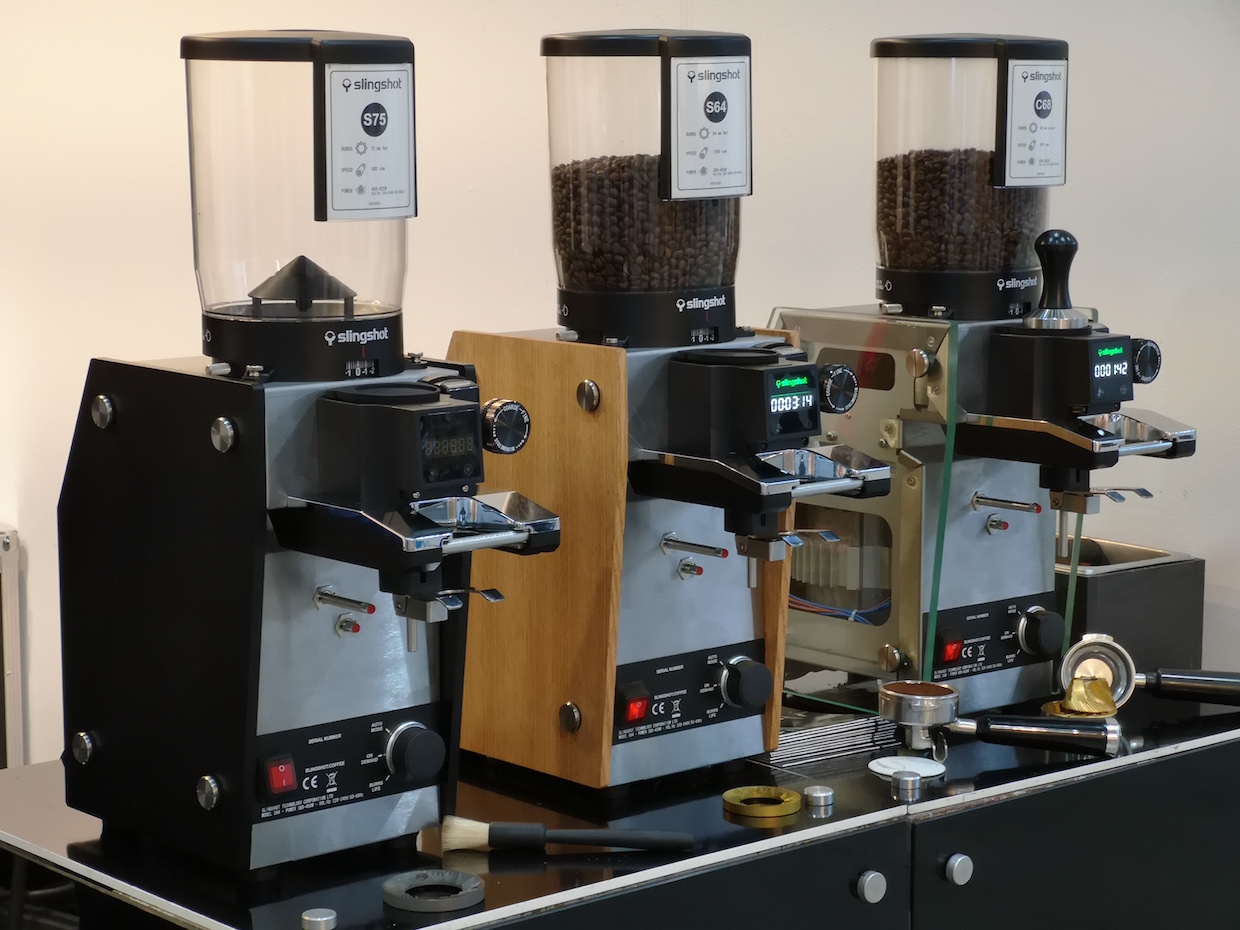

Currently emerging from Australia, the Slingshot grinder takes a novel approach to the doser concept. A smaller chamber neatly dispenses precise, user-settable doses without thwacking. With a variety of other features, the Slingshot aims to preserve the traditional benefits of a doser-type grinder, while adding several capabilities not found elsewhere.

The Slingshot made its first public appearance at the Cafe International Show in Seoul last month. Its design centers on a compact dosing chamber that includes its own mechanical “volumetric” dosing system that the company claims will promote greater coffee freshness and ease of use compared to traditional doser systems.

Whereas standard dosers can hold upwards of 300 grams of ground coffee, the Slingshot doser contains only about 30 grams, according to the company. It also has a mechanism for recognizing which portafilter has been inserted and then dispenses the correct barista-designated dose for that portafilter, accurate to within roughly half a gram, the company says.

The chamber also has an integrated stirring mechanism that promotes an even distribution as grinds neatly descend straight down into the portafilter without spillage. In automatic mode, the grinder reflexively grinds another 30 grams into the doser every time the chamber is emptied. A simple digital timer on the outside of the doser then starts counting the seconds since the last dose was ground.

The Slingshot offers an on-demand mode for times when business slows down. Other features include the ability to open the grinding chamber for cleaning without losing the grind setting, a hopper lid with a built-in flap that hangs down for displaying info about the coffee, a detachable power cord for easily moving the machine around, and fully customizable outer case panels.

Multiple grinders can be connected in modular fashion. Beyond the “ample ventilation” the company said is built into the case, there’s also a fan to draw heat out from the interior and the grinding system is belt-driven to further keep the motor’s warmth away from the coffee.

Dosages and the grind settings are both micro-metrically adjustable by manual knobs. A built-in grind-time memory function provides notification of when the burrs are nearing the ends of their projected usage lives, and a resettable zero-point indicator on the adjustment collar provides a helpful orientation for when more adjustments occur throughout the day.

“It is a very simple, elegant system,” Slingshot system inventor Luca Giorgella told Daily Coffee News, noting the total absence of anything smartphone or IoT-related. “Slingshot is simply mechanical. We have a digital display only for adding extra features, such as the coffee maturations time, the burrs life monitoring, etc. We wanted to create a simple machine that is reliable and is a precise grinder at an affordable price.”

Options include machines centered on either 65- or 75-millimeter flat or 68-millimeter conical burrs, all custom designed by Macine Keber and upgradeable to titanium or “red speed” burrs. While prices are not yet confirmed, Giorgella said the machines are expected to range from $1,500 USD for the 64-mm flat burr version up to $2,000 for the 68-mm conical, excluding taxes.

Though the Slingshot Technology Corporation Ltd. is officially based in Hong Kong, Giorgella lives in Australia where a pre-production run of 30 units is currently spread out in the field for testing. The company said production for the Asia Pacific market will start at the end of March 2019, and the machine’s debut on U.S. soil will be at the SCA Expo in Boston in April 2019.

Giorgella, whose 20 years in the coffee industry have seen him in various roles, currently including a director position at Segafredo Zanetti Australia, said that the new company is also working on projects beyond the Slingshot. Future products are slated to include an automatic tamper, followed by a “zero retention” espresso grinder for lower volume or home use, plus one more project Giorgella would currently only describe as “top secret.” The first version of the Slingshot grinder for the U.S. market is expected to become available by the third quarter of next year.

Howard Bryman

Howard Bryman is the associate editor of Daily Coffee News by Roast Magazine. He is based in Portland, Oregon.

Comment