Greek industrial equipment maker IRM Coffee Roasting Machines took a major step into artificial intelligence with the launch of new roasting profiling and automation software for all its hot-air machines.

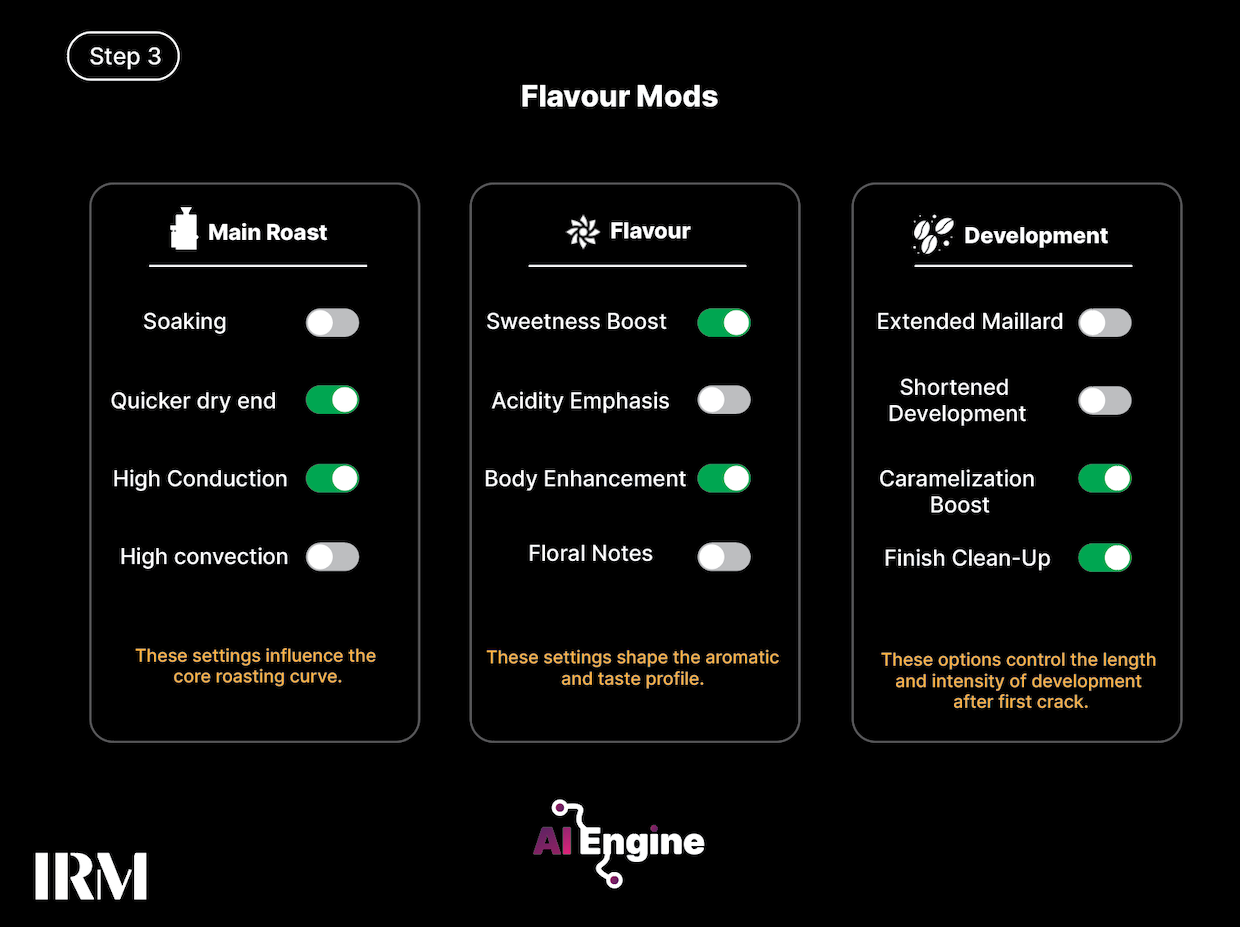

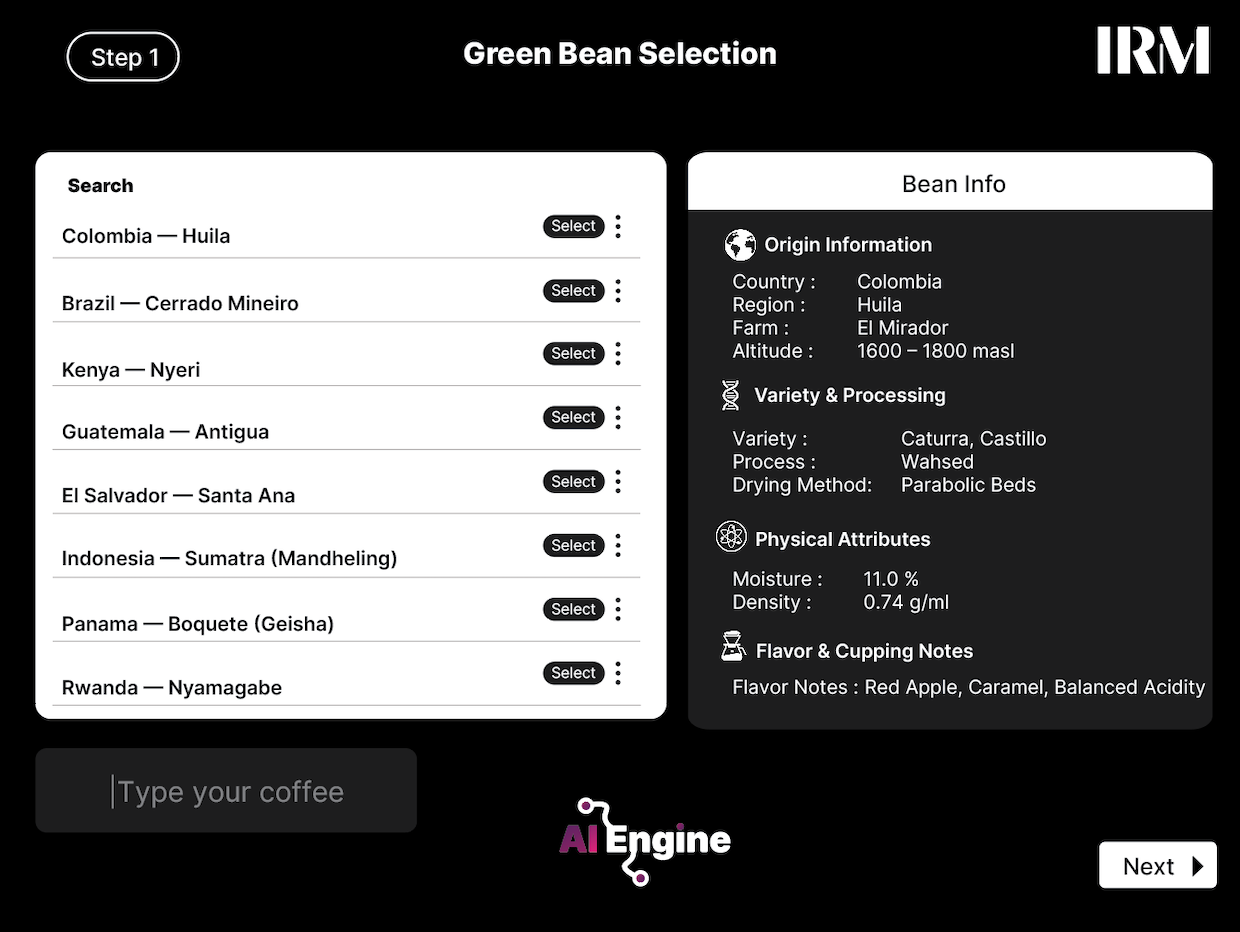

Unveiled at last month’s World of Coffee trade show in Geneva, the IRM PRO-AI system was developed in-house to analyze changes in temperature and rate-of-rise, comparing measurements to previously approved roast profiles in order to make real-time adjustments during the roast. Heat, airflow and drum speed can all be automated through the system.

IRM PRO-AI is also designed to integrate with the company’s roast process monitoring and control platform, called Kai-Zen, which was introduced in late 2023. While IRM machines still fully support Cropster and Artisan integrations, Kai-Zen offers native control, logging and machine feedback tailored specifically to IRM systems.

Kai-Zen also provides detailed machine diagnostics, stores and supports edits to roast data, and provides a portal for live support requests.

“Kai-Zen is not required for the AI Assistant to function, but when used together, the integration unlocks the full power of autonomous control, process analysis, and predictive adjustments,” IRM Founder and Owner Ioannis Papadopoulis told Daily Coffee News. “More than just software, Kai-Zen reflects the transparent way we do business, and our continuous commitment to improving the performance and longevity of our machines.”

IRM machines roast coffee by sending a flow of heated air that passes upwards through the entire mass of coffee beans via perforations in the drum. The company’s atypical drums are cylindrical on the bottom and polygonal at the top, which the company says prevents beans from getting pinned against walls by the powerful airflow. Custom flaps gently agitate the beans while roasting.

IRM grew out of IP Cad Constructions, which was founded 22 years ago as a parts manufacturer with a strong interest in upgrading and rebuilding coffee processing equipment. In 2017, the first IRM branded machine launched, and the company now offers eight models ranging in capacities from 1.5 to 140 kilograms.

All machines are manufactured in Greece and all models are available with either natural gas or electric heat sources.

IRM also offers airtight green coffee silos with humidity and temperature sensors, automated transfer systems for both green and roasted coffee, and airtight roasted coffee silos equipped with auto-degassing valves and sensors that analyze post-roast coffee behavior.

“From our smallest model to the largest industrial model, all machines are built on the exact same core principles: identical air technology, identical electronics, and the same professional approach to control, efficiency, precision, and repeatability,” said Papadopoulis.

All new IRM models come standard with Kai-Zen, while the PRO-AI system is an optional upgrade. Retrofit kits for existing machines are also available upon request. Pricing varies depending on machine size, training packages and other factors.

While the company seeks to grow its presence in the United States, IRM machines are ready to ship worldwide now. The company also remains at work on deepening its AI integrations into green-coffee-related tasks for full production workflow solutions.

“We are focusing especially on achieving seamless collaboration between all the processing modules we manufacture,” said Papadopoulis. “All systems run under a unified Mitsubishi automation backbone, tightly integrated with our in-house AI engine, which we are actively developing to bring a new level of intelligence to the entire roasting operation.”

Comments? Questions? News to share? Contact DCN’s editors here. For all the latest coffee industry news, subscribe to the DCN newsletter.

Related Posts

Howard Bryman

Howard Bryman is the associate editor of Daily Coffee News by Roast Magazine. He is based in Portland, Oregon.

Comment