Admittedly, we’ve lately been going a little crazy for transparent portafilters. But like their makers, we’re obsessed.

Here, Amsterdam-based Tije, the maker of the latest known transparent portafilter, takes us through the first part of his production process. Inspired by Stephen Sweeney’s portafilter, Tije’s method is arduous, especially since no known acrylic-based transparent portafilters have proven to withstand repeated use in commercial applications.

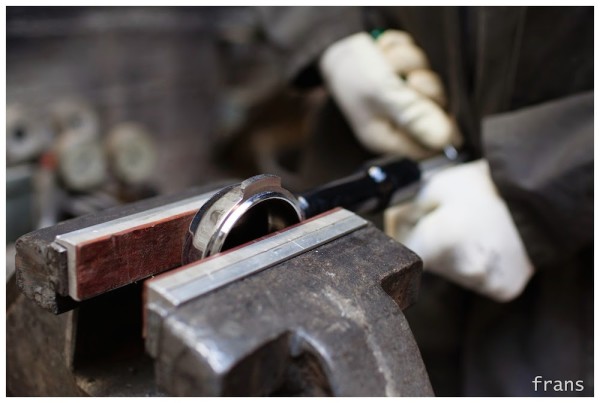

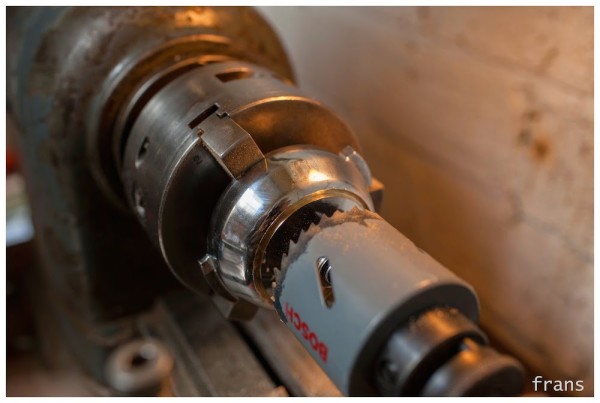

Frans Goddijn, the man behind the camera documenting Tije’s work for his Kostverlorenvaart blog, with permission gives us step-by-step photos of this labor of love:

At this point, the acrylic is transparent from top to bottom, but still cloudy on the sides and too big for the basket

Nick Brown

Nick Brown is the editor of Daily Coffee News by Roast Magazine.

Comment