After traveling 20 minutes from Popayán, a sprawling, historic city in Western Colombia, I surveyed the land before me and pondered the immense change that has taken place. Just a few years ago, this location surrounded by verdant rolling hills within sight of the Puracé volcano was an active conflict zone. Now it’s the site of TECNiCAFÉ, a science and technology park that holds much promise for the future of Colombian coffee.

TECNiCAFÉ is a public-private partnership founded on Oct. 1 2015, on International Coffee Day, that began operations in 2017. Formulated by the visionary César Echeverry, TECNiCAFÉ serves as a technology incubator, experimental farm, and research center modeled after the famous Stanford Research Park. By providing these tools, TECNiCAFÉ works toward achieving its primary goal of developing ways for producers to regain the long-lost value of coffee production.

TECNiCAFÉ also functions as a training center for the coffee industry, and it is this feature that has brought me to the technology park on this occasion. I was accompanying a group of students taking part in CQI´s latest industry-shaping initiative, the Q Processing program, which is the brainchild of CQI Technical Director Mario Fernández. Because processing is one of the most direct ways to impact and improve coffee quality, the Q Processing program has the potential to have as great of an impact on the coffee industry — or perhaps even greater — than the global standard for quality evaluation, Q Grading. There are currently two levels for Q Processing: Generalist (Level 1) and Professional (Level 2), with Expert (Level 3) in its final design stage and ready for deployment in 2019.

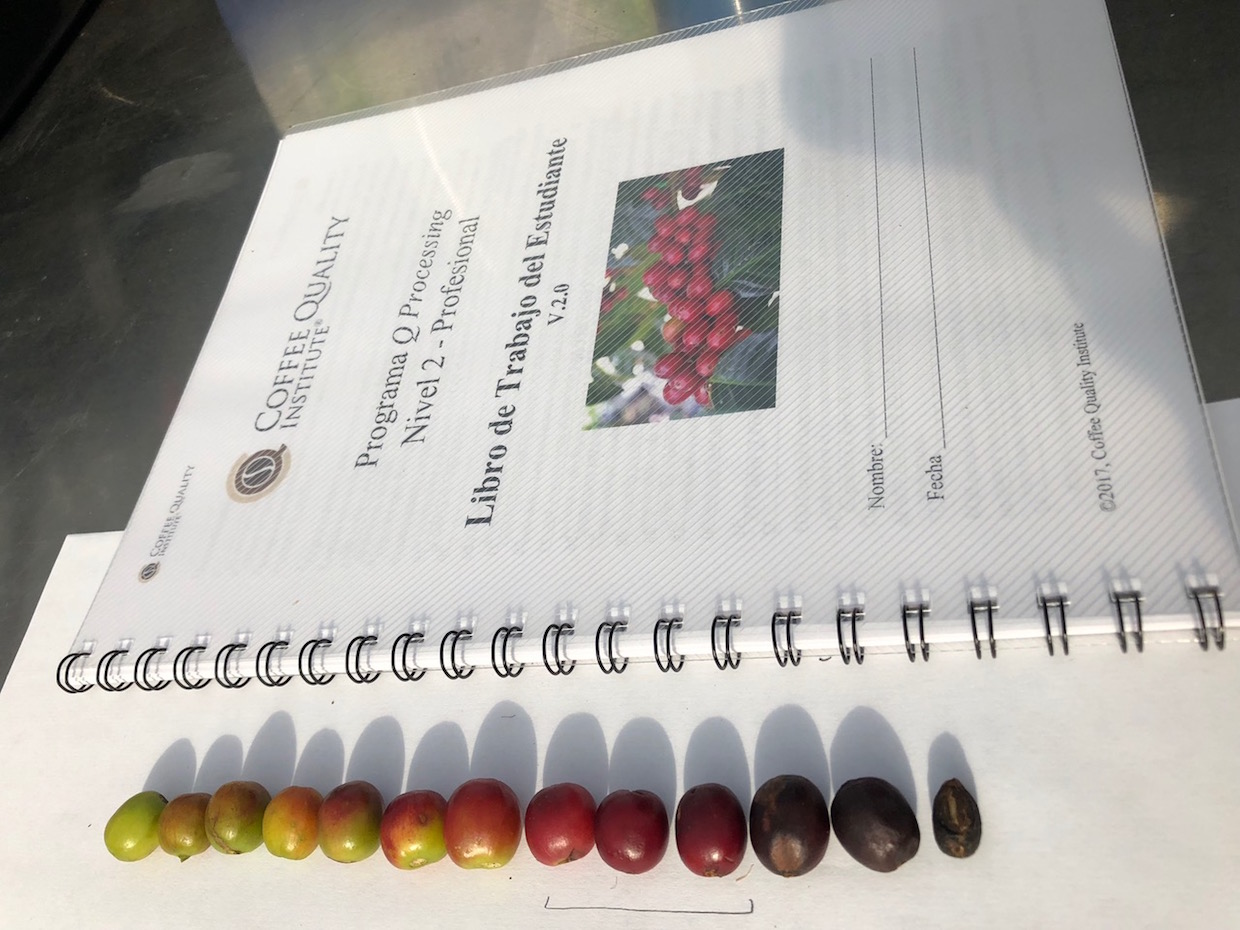

TECNiCAFÉ’s location inside a 40-hectare experimental farm makes it the ideal location to carry out the Q Processing course. As I watched the students attempt to achieve Q Processing certification, I recognized the program is not only designed to formalize the coffee processing experience and knowledge the world has developed. It is also challenging conventional wisdom, and even shattering long-standing preconceived notions of cherry selection, pulping, fermentation, drying, and storage techniques. Additionally, Q Processing applies a scientific rigor that has long been lacking in our dear industry.

In an era of international coffee prices below cost of production for most growers, it is the drive for improved quality, increased efficiency and climate resiliency that will place producers on the right path to not only survive, but to remain viable over time. Q Processing may be in its initial phase, but it could be the platform that defines what it’s like to be a coffee grower in the 21st century.

Toward the end of my visit to TECNiCAFÉ, I walk past Kent and Gesha varieties, futuristic drying modules, optical sensors for coffee cherry selection and apps for farm management. I marvel at what technology can do for producers all over the world. Unable to contain my enthusiasm, I dreamt of the possibilities. Then César walked me to his office and said, “But the greatest impact of our work is right here, in the surrounding communities. Cauca has a poverty rate of 60 percent and extreme poverty of 30 percent, mostly of folks of indigenous and African descent.”

TECNiCAFÉ is clear evidence that transformational change is possible. What was once a conflict zone is now a thriving campus promoting coffee’s future. And the Q Processing Program will contribute greatly to that future, giving coffee professionals the opportunity of a generation to get the tools they need to produce the coffees that the world demands.

[Editor’s note and disclosure: Author Jorge Cuevas is a CQI board member. This story originally appeared in the CQI blog and has been edited and republished here with permission as part of an unpaid editorial collaboration.]

Jorge Cuevas

Jorge Cuevas is the Chief Coffee Officer of Sustainable Harvest. He has extensive experience building organizations within the specialty coffee industry, and for over 20 years has helped smallholder coffee farmers reach global markets.

Comment