A common piece of advice for coffee roasters is to make sure they’re connecting their detailed roasting records to their cupping or tasting results, in order to develop the experience that allows them to quickly diagnose roasting issues and understand how roasting plans can be changed to improve their roasts.

Often left out of that advice is what they should be looking for in that roasting data, and how to meaningfully connect those differences to the differences they find in the cup. The best approach that I’ve found for this is a technique called Profile Translation Analysis. This is translation in the geometric sense, not a linguistic one. It involves shifting the chart of bean temperature over time along the time axis, to more easily compare the similarity of multiple batches of coffee within specific temperature ranges (see end of story for examples in graph form).

When coffee is roasted, there is a very large network of chemical changes that occur, resulting in the creation of hundreds of new molecular species that are responsible for different characteristics of the finished brew.

All of these different reactions require two things to occur. One is that the reactants must be present and available, and the other is that there must be enough energy for the reaction to start. Some of these reactions depend on chemicals produced from other chemical reactions occurring either before or simultaneously. It’s important to remember that these changes do not take place instantaneously, but rather progress over time.

Looking at many of the important chemicals involved, you’ll often find that at a certain point in roasting, a chemical will start being produced, but later in the roast the concentration of that chemical will go down as it is either broken down into other chemicals or is used in some other reaction. The important point here is that changes in the rate at which coffee passes through one range of temperatures will have a different effect on the cup than a similar change in the rate at which coffee passes through an earlier or later range of temperatures. In other words, two batches of the same coffee roasted to the same ending temperature in the same total time may still taste very different from each other.

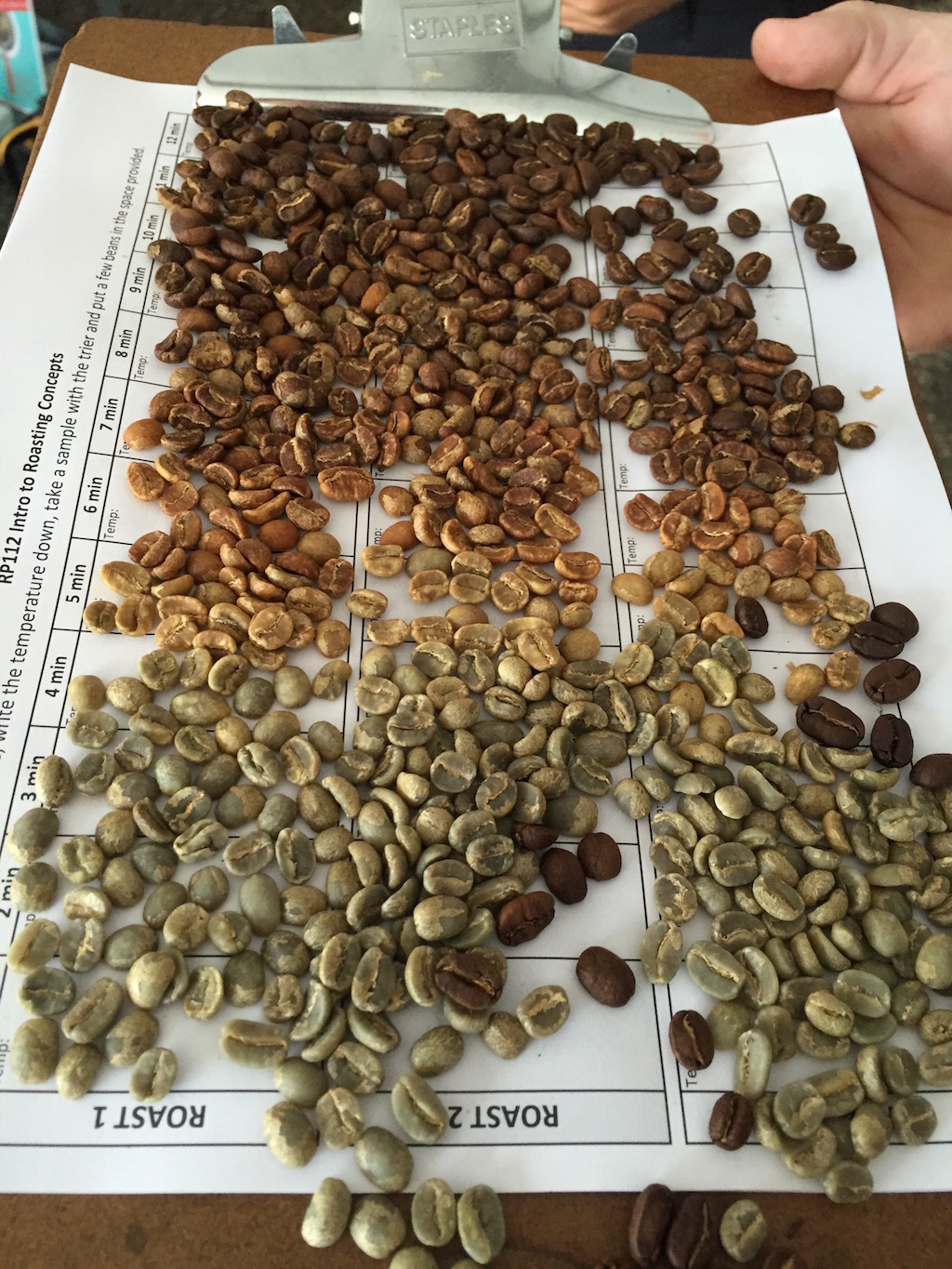

Easily Observable Physical Changes

A good place to start with profile translation analysis is to examine ranges that are marked by easily observable physical changes. Examples of ranges include: the start of the roast through the start of the color change from green to yellow; from there through the start of the change from yellow to brown; from there through the start of first crack; from the start of first crack through to either the end of the roast or to the start of second crack; and, if applicable, from the start of second crack through the end of the roast.

In a roaster with good instrumentation, these events should be happening at consistent bean temperatures. Each measurement we collect is both a bean temperature reading and an amount of time that has elapsed since the start of that batch.

Suppose we have one batch of coffee where the first color change starts 370 seconds into the roast and another batch where the change starts at 373 seconds. If you wanted to compare the two batches only within the range of where the coffee is yellow, you would subtract 3 seconds from every measurement in the second batch. This aligns the two batches at the start of that range and if the data is graphed and overlaid visually, it’s easy to see if temperatures changed in that range in the same manner, or if the variance in their rate of change from earlier also continued into that range.

The exercise can be repeated for other ranges, noting where things seem to be the same and where there are substantial differences. In repeating this with many batches and comparing how these coffees taste, it becomes possible to draw correlations between specific sensory differences and differences in the coffee’s progression through specific temperature ranges.

If you have access to some of the academic work on coffee roasting chemistry, you’ll find that this way of looking at roasting data also makes much of this research more accessible for practical use at the roaster. There is no need to restrict the ranges compared to those bordered by physical changes. For example, if there are specific chemical reactions of interest, you can align the roasts at a temperature corresponding to the activation energy for that change.

Controlled Experiments

Once you’re comfortable with using profile translation analysis, it’s easy to move on to controlled experiments: Roast a batch of coffee in a way that’s typical of what is easy to do on your machine, then isolate a particular temperature range and roast a couple batches that progress through that specific range faster and a couple slower, taking care to keep all other rates both before after the selected range consistent from batch to batch. Then cup or otherwise taste the results.

This is much easier to accomplish if you plan these roasts in advance and attempt to match those plans for each roast. In some ranges the differences will be dramatic, in others the differences will be more subtle. In the earliest portion of the roast where nothing interesting is happening chemically you’re likely to find that in a triangulation or a 2 of 5 test, batches with differences only in that early range cannot be reliably distinguished unless there are roast defects such as scorching.

Repeating these exercises with different coffees, you’ll find that some of these differences are very consistent from one coffee to the next while others depend more on the inherent character of the coffee. A good summary of these changes can be found in Rob Hoos’s book, “Modulating the Flavor Profile of Coffee: One Roaster’s Manifesto.” In addition to reading that book, I’d also encourage roasters to conduct their own experiments to gain direct, first-hand experience.

Mastering profile translation analysis gives roasters a powerful tool for understanding the cause of unwanted variations in production as well as the experience to make changes in a roasting plan to produce specific, targeted changes that are desired in the finished product. It can be used to provide a deeper understanding of any coffee and can be put to practical use with any roaster that has good instrumentation and controls.

- Two batches under comparison with no transformation of the data. We might suspect that these batches will taste different, but it’s not easy to see where the most significant roasting differences are due to the purple batch starting at a higher temperature and overshooting the attempt to compensate for this prior to the start of chemical changes in the coffee. The background is color coded to show where the coffee starts to change from green to yellow, where it starts to change from yellow to brown, where first crack starts, and where second crack starts. As always, these measurements will vary among different machines.

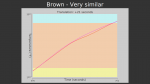

- A 24 second translation so we can see how the batches compare when the coffee is yellow. That part of the roast is very similar, but looking to the end of the batch it becomes clear where the two batches really start to deviate about mid-way between the start of first crack and the start of second crack.

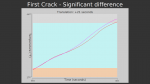

- A 21 second translation to align the batches at the start of color change from yellow to brown. The same translation aligns the batches at the start of first crack.

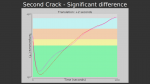

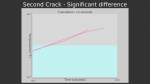

- Aligning the batches at the start of 2nd crack, and we can see that there’s a significant difference in time from this point to the end of the roast between these two batches.

- A close up of the 24 second translation to compare the yellow range.

- A close up of the 21 second translation to compare the brown range.

- The same 21 second translation to compare from the start of first crack, showing where there’s a significant difference between the two batches. The red line is slowing down more in this range.

- A 2 second translation for comparing the portion of the roast after the start of 2nd crack. The red batch starts out a little slower but reaches the end point significantly faster.

Neal Wilson

Neal Wilson has roasted coffee at Wilson's Coffee & Tea since 2000. He is an SCAA specialized instructor, a YouTuber (N3Roaster), and the author of Typica, a free program for coffee roasters.

Comment

1 Comment

Comments are closed.

This is a fantastic post! Super informative. Love it.

Thanks,

Andrew – Coffee Scout Australia

http://www.coffeescout.com.au