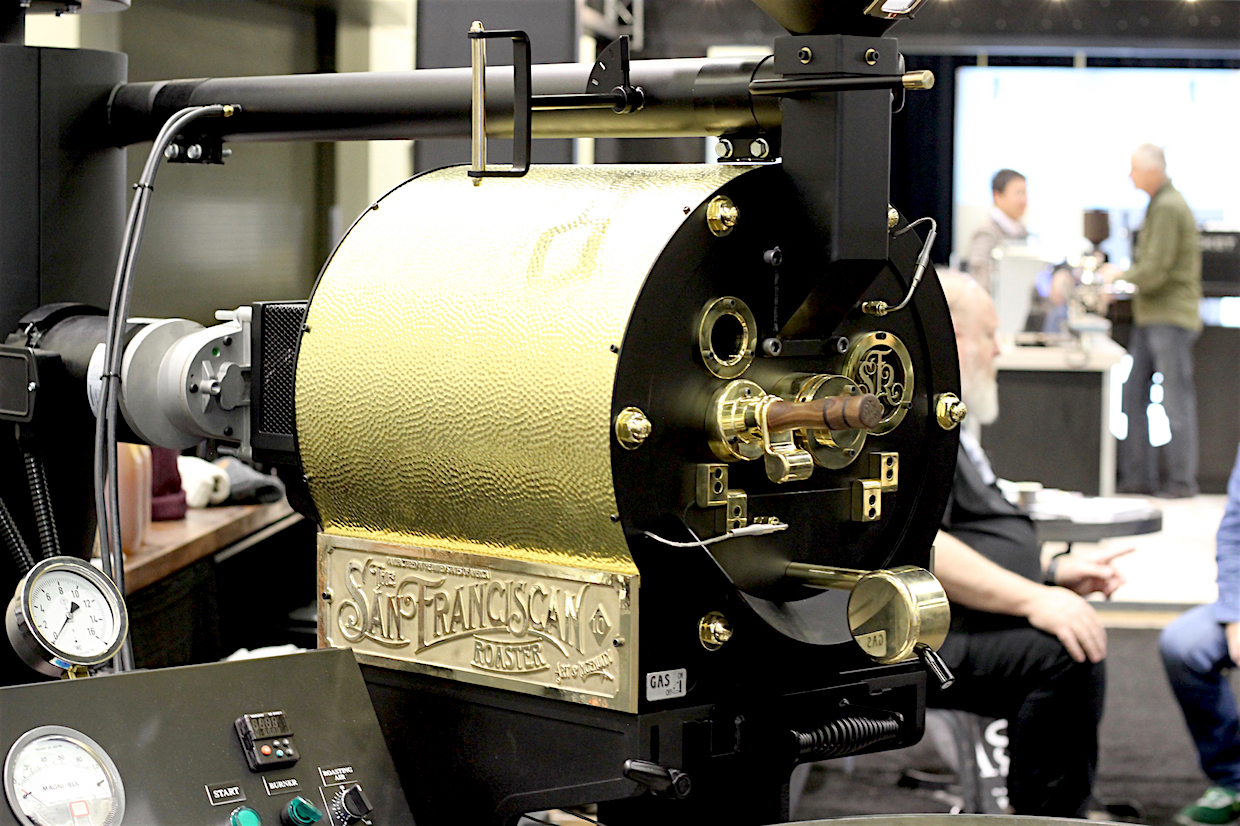

The San Franciscan SF10 10-pound-capacity roaster on display at the recent SCA Expo in Seattle. Daily Coffee News photo by Lily Kubota.

The San Franciscan Roaster Company has added new machine to its lineup, the 10-pound-capacity SF10, sized strategically to land within the financial and sometimes legal means of start-ups and other companies in early growth stages.

Previously the San Franciscan selection jumped from the SF6 straight up to the SF25. The new model bridges that considerable divide, while also falling just beneath a common air quality regulatory limit on roasting machines that can operate without a legally required smoke mitigation solution.

“Ten pounds or five kilos is their magic number,” San Franciscan CEO Bill Kennedy told Daily Coffee News. “Anything above that batch size is where they draw the line for getting permits for emissions and so on. But it’s also a great size for a lot of small roasters that want to do more than just a 2.5 or three kilos per batch, but maybe they don’t have quite the start-up capital to get going with a whole 12-kilo roaster.”

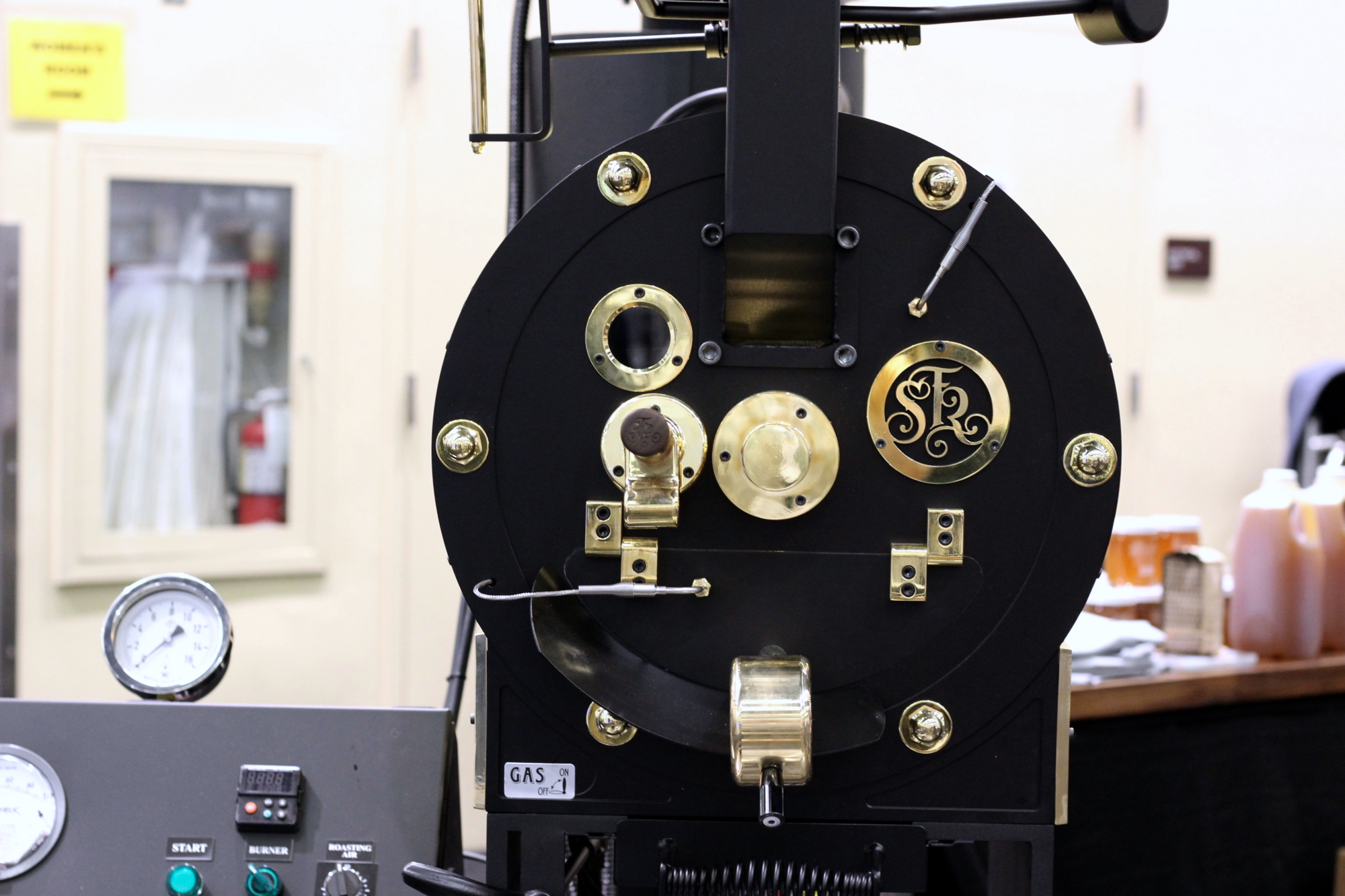

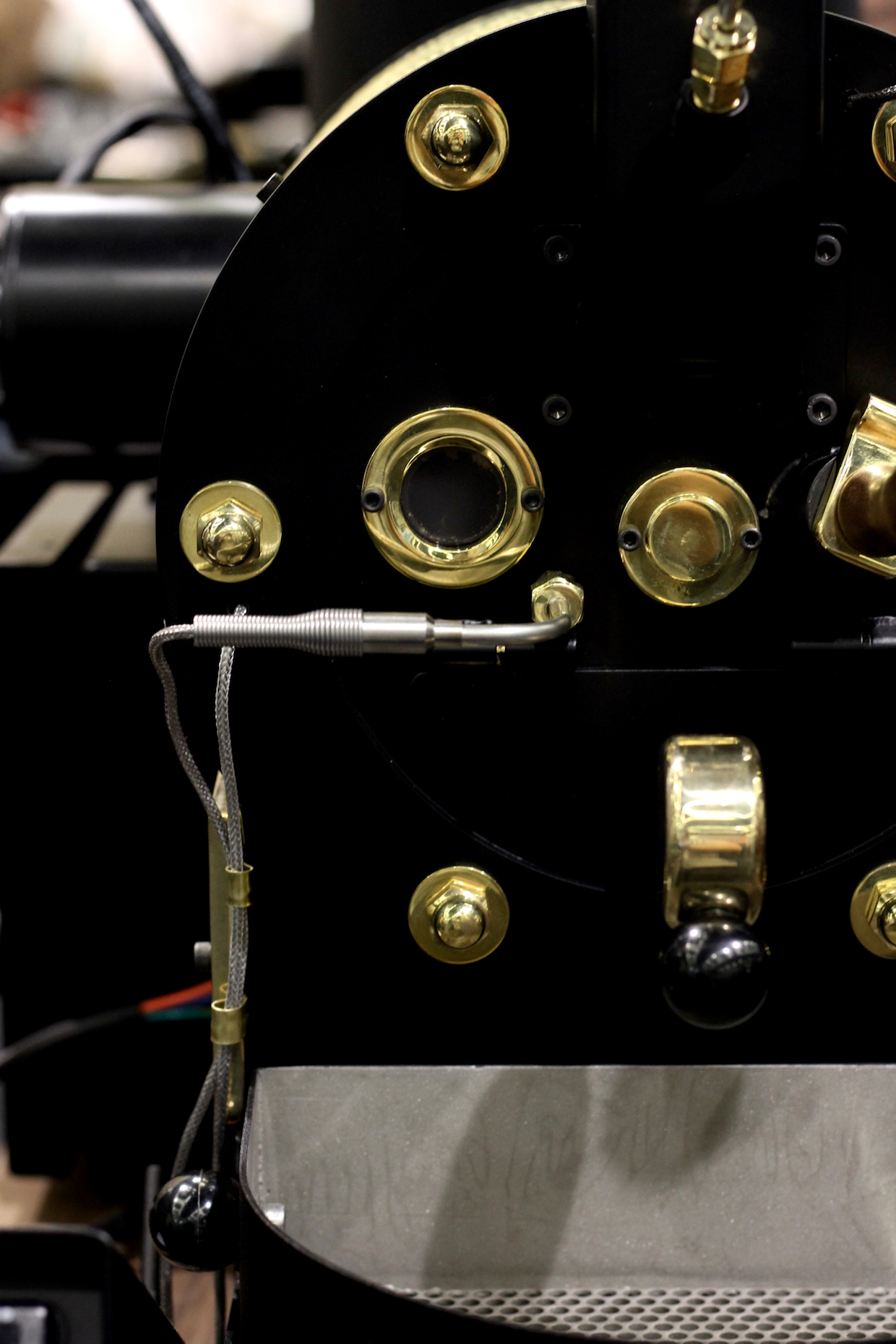

Beyond the particulars of capacity and emissions, the SF10 offers the same build quality as any other SF machine, and also many of the same internal parts and components as the larger SF25, allowing for potentially longer life of peak performance from parts that are pulling a somewhat lighter duty in the smaller model. The common components also allow for an easier transition up to a larger San Franciscan when a user’s business grows. Said Kennedy, “There’s a lot of interchangeability; it’s very easy to scale up.”

Controls in the SF10 include variable drum speed, and both a mechanical damper and a variable hot air circulation fan, allowing users to adjust air velocity as well as pressure.

“We have a Magnehelic meter so you can measure the pressure in the system, and draw whatever conclusions and corresponding data points along with your roasting profiles,” said Kennedy. “Cooling times are brilliant because we use the same cooling mechanism as we do on the 12-kilo. It’s a little bit of a hot rod for a coffee roaster.”

Kennedy said pricing for the SF10 comes in at just under $30,000. The company started accepting orders upon revealing the new machine at the SCA Expo in Seattle last month, with 90- to 100-day lead times. Like all San Franciscan machines, each one is handmade in the United States.

“Every piece of steel you see on there is hand-formed and cut and welded right in our shop in Carson City, Nevada,” said Kennedy. “The whole thing is American craftsmanship. The side-plates we still have done in the San Francisco Bay Area. We have a guy in Jackson, California, he hand-spins [the hopper]. It’s a fascinating process.”

Howard Bryman

Howard Bryman is the associate editor of Daily Coffee News by Roast Magazine. He is based in Portland, Oregon.

Comment

1 Comment

Comments are closed.

Need a quote of 12kg Roasting Machine, with landing cost to Australia.