Read the Introduction to Brewer Basics (Part 1) here

Water is crucial in making coffee. All brewers combine relatively simple engineering systems to produce a complex product, and water is perhaps the best example of that.

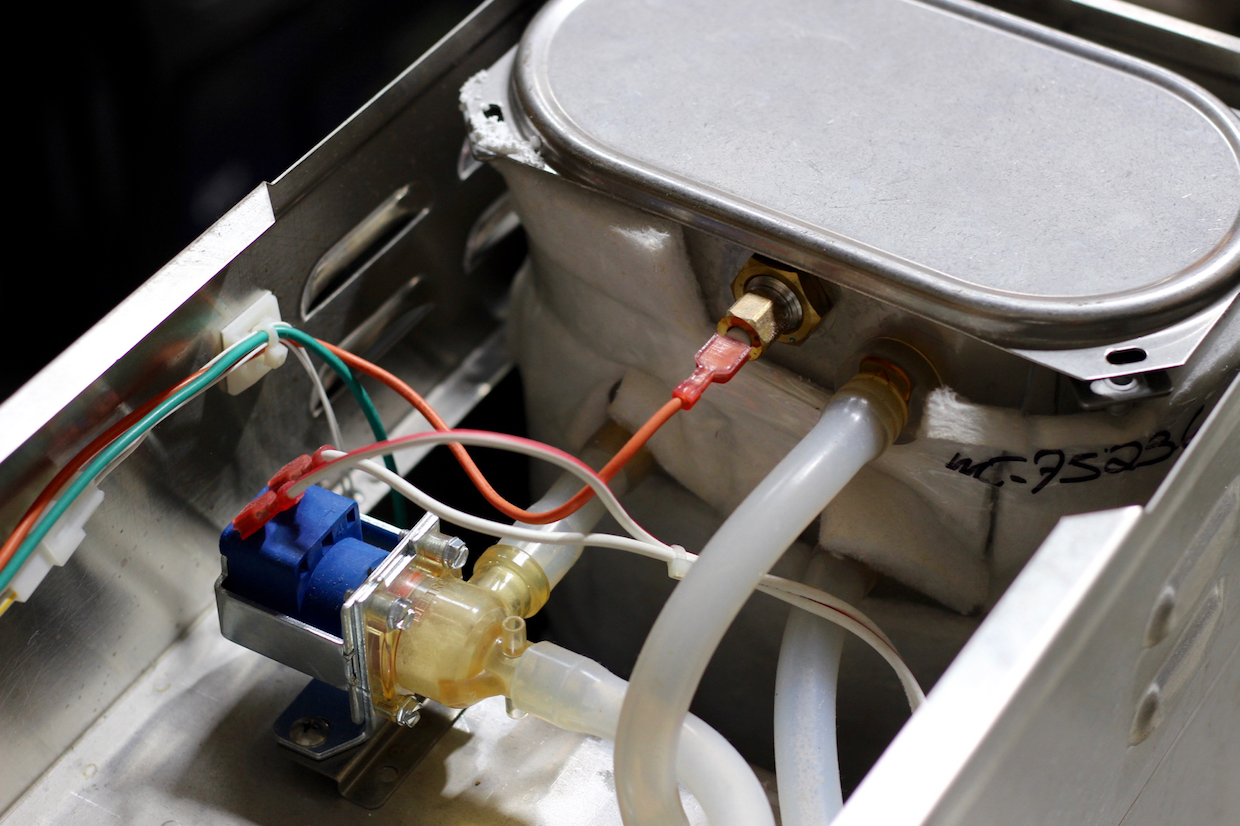

At its simplest level, a water system is composed of three primary components: the water inlet valve; the water level probe; and the water level control board. Each of these components have a specific function, but all three need to work in conjunction with each other to brew that delicious cup of coffee.

Water Inlet Valve

The inlet valve can usually be found near the incoming water supply on a brewer. Its principal responsibility is to manage the entry of water into your brewer. The water inlet valve acts as a sort of gatekeeper by allowing water to flow into the tank when it receives certain electrical signals from the control board.

It is a solenoid valve operated electrically by the solenoid or electrical coil. The solenoid has two positions: open and closed. When the solenoid is electrified it produces a magnetic field that opens the valve for water. The plug on the valve is very sensitive to hard water and obstructions — even if small grains of material get caught in it, it can stay open and the brewer would overflow.

Water Level Sensor, Or Probe

The primary function of the water level sensor, or probe, is to maintain the water level in the tank. The probe is usually insulated and should not touch any metal of the tank or the brewer shell. Touching any metal will ground it and will make it inoperative. When the water level drops below the required level, the open circuit tells the water level board to open the inlet water valve. It will call for water, and once the water hits the probe, it will create a closed circuit and will signal the water level control board to stop the water flow.

The probe is incredibly sensitive to hard water. A common problem is that the probe will have built up on its exposed part, leading it to overfill.

Water Level Control Board

The function of the level control board is to maintain the water level stays constant inside the heating tank. It is activated by the signal from the level sensor or probe and energizes the coil of the inlet valve to open it or close it. This board works in conjunction with the heating system to tell it when it’s full so the brewer can start heating.

[This article is appearing as part of an unpaid editorial collaboration between DCN and the Coffee Technicians Guild. It was originally published in the CTG blog and is republished here with permission. The Coffee Technicians Guild (CTG) is an official trade guild of the Specialty Coffee Association (SCA) dedicated to supporting the coffee industry through the development of professional technicians.]

Hylan Joseph

Hylan Joseph is the West Coast service manager for Espresso Partners and is the current chair of the Coffee Technicians Guild Leadership Council.

Comment

1 Comment

Comments are closed.

“The probe is incredibly sensitive to hard water.”

And in true Italian fashion, no improvement has ever been made in its design 🙂