Since opening one of Seattle’s earliest artisan espresso shops in 1988, one of the defining characteristics of the craft behind our counter has been the grinding of coffee for each shot, literally on demand. This is now the standard practice for virtually all specialty coffee establishments, making the grinder’s role industry-wide a demanding one.

That said, I’d like to lead with what might be a controversial claim: No single grinder currently available incorporates the full suite of capabilities needed to improve the quality or efficiency of artisan espresso at the highest standards.

The majority of on-demand grinders presently produced by the industry are adaptations of old designs that had a dosing hopper to store and crank out ground coffee. All grinders of this type have chambered ground coffee trapped within the grinding head and dosing systems. This is fundamentally inadequate for artisan espresso preparation. Our revolution is stymied firmly by this equipment barrier.

A condensed list of additional features and capabilities critical to an espresso grinder includes:

- Retention of less than 1 gram (g) of chambered ground coffee

- Grinding output speed of no more than 2g per second.

- Propulsion of powder into the portafilter with no clumping or micro-particle drift

- Cessation of grinding upon achieving an exact dose by gram weight (+/- 0.1g)

- Temperature Control: The powder must remain between 90°F to 95°F.

So let’s take a close look at why the grinder needs to incorporate all of the above features in order to consistently create thick, sweet caffè espresso.

Flow Rate

A perfectly even saturation that offers just the right resistance to the pressurized water is at the heart of the espresso method. How fast the water passes through the packed coffee is referred to as flow rate. At Espresso Vivace, the flow rate for our ristretto shot yields 25 ml of crema in the cup within 27 to 32 seconds from the moment the brewing switch is activated.

In general, espresso is very sensitive to the flow. Provided a balanced roast that preserves a coffee’s caramelized natural sugars and origin-related characteristics, a too-fast shot that reaches full volume in less than 25 seconds will have a flavor profile dominated by sour/astringent notes. Too slow, extracting 25ml in 33 seconds or longer, and the flavor might be hollow, sour, or bitter.

What fascinates me, after 31 years of daily immersion in this art, is the fantastic range of flavor profiles that exist within our window of 27 to 32 seconds. For example, a 28-second extraction might be dominated by a chocolate umami and blueberry from the Ethiopian Sidamo, and a 30-second shot might have salted caramel come forward from the Indian Malabar. With a total of four beans in our blend, the shadings of flavors are very nuanced with different extraction times.

What features are key in maintaining an ideal flow rate of the shot?

Stepless Grind Setting Adjustment

In artisan espresso preparation, grinding by the cup is now standard practice worldwide. We all adjust the grinder often in response to environmental changes, particularly humidity, in the shop. Any grinder needs continuous, stepless grind adjustment capability, rather than stepped settings. Most grinders succeed here.

Dosing by Weight

A consistent flow rate can only be achieved if the gram weight of the ground coffee dosage is very consistent. I tell students that an increase of 1mm in the height of the packed coffee slows down the flow by 10 seconds. Yet without weighing the grounds, dosing by feel is a very difficult barista technique. To that end, the grinder must weigh the ground coffee, and shut off when the desired gram weight is achieved. Very few existing grinders offer this feature.

Low Retention

In a very busy shop, ground coffee retained by a grinder while the motor is off between shots is not so much a “freshness” problem, as grinds are likely to be expelled with the next dose before losing too much vitality where flavor is concerned. It’s the incredibly fast-changing levels of moisture in ground coffee that presents the main obstacle.

Roasted coffee still contains moisture within it — some coffees more than others. More moisture in the bean requires a coarser grind; less moisture requires a finer grind to perfect the pour. At Vivace, our grinders feature a grinding chamber around the burrs that traps about 6 grams of ground coffee when the motor is shut off between shots.

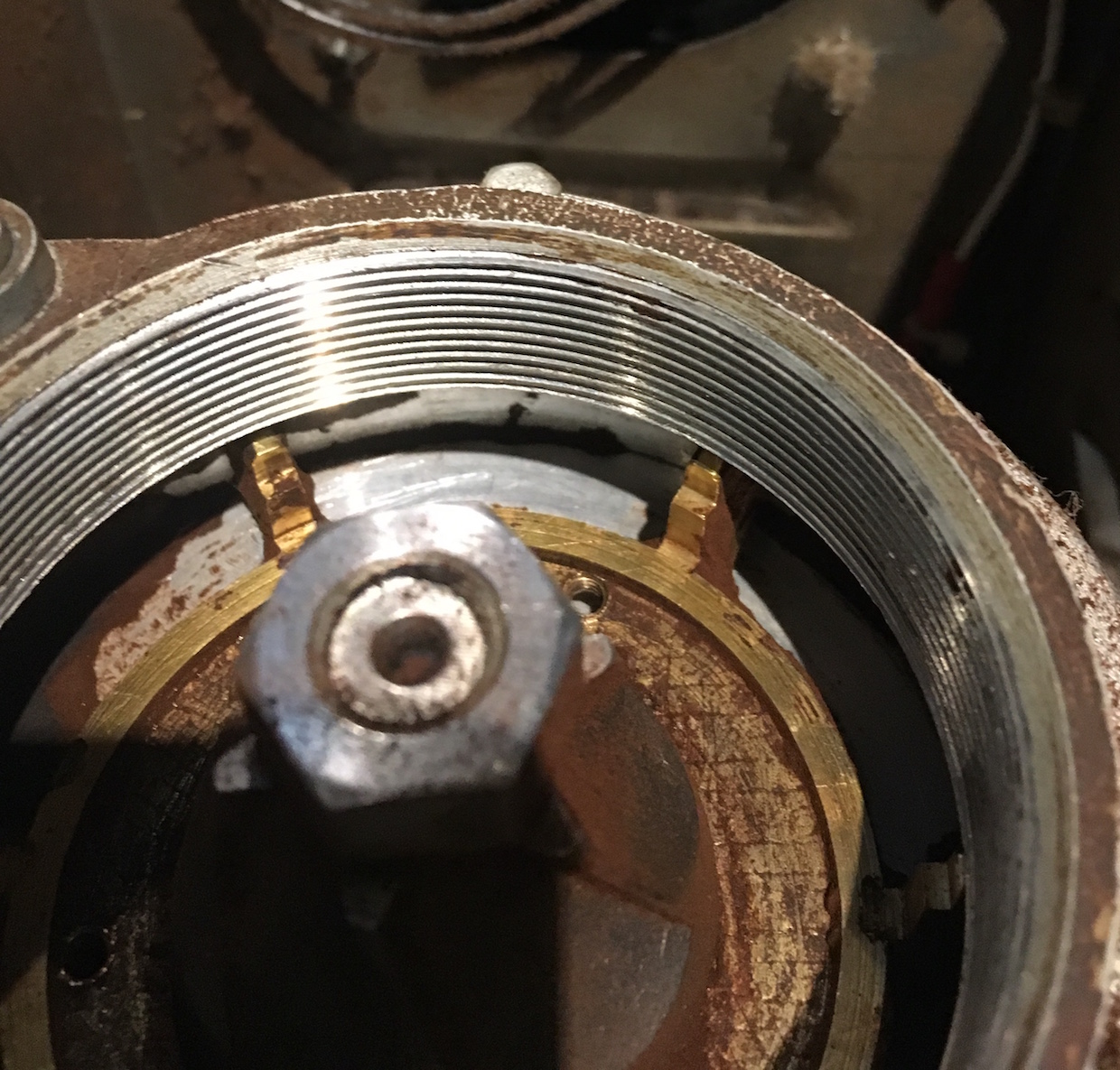

With the lower burr removed the grinding chamber and impeller paddles are visible. This circular chamber traps about 6g of powder.

There is also then a horizontal port through which ground coffee is impelled by the grinding head out into the dosing cone attached to the front. This exterior cone design is the vestigial mechanism I mentioned earlier, indicative of a system fundamentally incompatible with artisan espresso; a holdover from the days of the Italian dosing hopper with the flapper to dispense ground coffee.

The horizontal port traps an additional 6 grams of ground coffee between shots. Our total chambered ground coffee is therefore about 12 grams. As we dose to about 21 grams per shot at Vivace, 12 grams is more than half a shot, laying in wait to throw baristas off their game.

Impeller paddles in the grinding chamber spin and push the powder horizontally through the chute which holds about 6g of powder.

As retained coffee sits in a warm grinder, it immediately begins to desiccate. As it quickly loses moisture, its resistance to pressurized water changes. Even within one minute on a humid day, our pour would go from 28 seconds to 24 seconds; and on a hot, dry day, the change might be even greater.

This phenomenon drives my baristas nuts. Based on the desiccated grounds, they adjust the grind finer because the shot poured too fast, then the next shot seizes up and pours way too slowly.

We train and train, “When it doubt, purge it out.” We purge 12g out of the grinder after it sits for one minute or more. Our grinder’s retention requires Vivace to run through 33g of coffee almost each time we make a shot. Our very busy baristas also sometimes forget how long the grinder has been sitting between shots, leading to many extractions poured straight down the drain.

Grinding Output Speed

While dosing mechanisms are the major problem I see with grinders on the market today, the speed of grinding is of equal importance. Ground coffee output speed is affected by the combination of burr size and RPM. In my experience, grinding faster than 2g/second makes thinner espresso, even with conical burrs. Many manufacturers have pushed output of their machines up to 6g/sec, resulting in weaker flavor and a thinner texture of espresso in the cup, although some grinder manufacturers have been introducing adjustable RPM.

Conical Burrs & Configuration

Many grinder manufacturers prefer flat burrs for the more uniform particle size they create, but I think that uniformity comes at the expense of pure espresso quality. I favor conical burrs because they produce micro-particles (fines) that add flavor and body to the shot compared to flat burrs.

Fines are produced because the heavy vanes in the conical burr squeeze the beans until they shatter, producing particles of all sizes. Then the fine teeth shear it into a regular size, adjusted by the barista, depending on atmospheric conditions that day. The fine particles slip through and are evenly distributed in the ground coffee.

The configuration of the conical burr set is also important. One manufacturer has chosen to drive the outer “female” half of the burr set with the motor, rather than the industry standard of powering the inner “male” or cone burr. There are tremendous gains in mouthfeel and flavor intensity with this innovation. Frankly, I have no idea why this works so well.

Particle Management

Though the fine particles produced by conical burrs add to the body and flavor of espresso, any static charge encountered by the grounds en route to the portafilter will gently pull them out of the powder because they are lighter than the larger particles. It is impossible to eliminate static charges with ground coffee moving over metal surfaces; therefore, a grinder’s dosing system will never allow the particles to free-fall into the portafilter.

Without a grind condensing mechanism, free-falling particles in the cone deposit only the fines on the metal.

The industry’s universally adopted solution to the static problem is to gently consolidate the grounds. Some manufacturers push the grounds through a little rubber curtain, while others use crossed wires.

At Vivace, I devised a “chain curtain” for our machines that offer a very gentle resistance to the coffee so that the fines are trapped in the powder with perfect fidelity to the original distribution pattern.

Whatever consolidation mechanism a grinder employs, on very humid days the grounds might clump and create back-pressure on the stream of powder. This causes inconsistencies in the form of unexpectedly slow extractions, because any significant back-pressure from the point of consolidation increases the time coffee spends within the burr set, resulting in a much finer grind.

One manufacturer solves this problem with a sort of propeller attached to the burr set — not twisty like for an airplane, but flat paddles angled downward. The propeller shoots the coffee directly down into a portafilter mounted very closely to the mechanism. The impact of the paddle surface consolidates the grounds, trapping fines instantly so no drift happens, while the very short distance the coffee travels downwards also minimizes particle drift from random static buildup.

Temperature Control

Heat builds up in any grinder, both from the motor being cycled on and off and from the act of grinding itself, which also produces heat. A simple solution to this is to vent the motor casing and grinding head with a fan that pulls the air through the machine.

For our grinders with a 500-watt motor, a small fan moving about 30 cubic feet per minute (cfm) of air stabilizes the grind temperature right in the low 90s, even when our bar is completely slammed on a typical weekend midday shift. I would love to claim this as an engineering triumph, but it was a lucky shot. This suggests that temperature control of the grounds is a minor engineering challenge overall.

A small number of grinder makers today are belt-driven to displace the warm motor further from the chamber, plus ventilated intentionally for additional temperature control, while at least one offers a cooler-running three-phase motor.

A Call To Action

In 2004, the espresso machine industry responded to research I led at La Marzocco in Seattle several years prior. Motivated by our findings, engineer Mark Barnett founded Synesso to create the first commercial PID controlled espresso machine, and in the years that followed, PID machines with stable brewing temperatures swept the industry.

These machines are capable of truly sweet espresso. However, grinder innovations have not been nearly as successful. After all, the espresso machine is responsible for the quality of flavor in the cup, while the grinder is responsible for the quantity of flavor in the cup.

So, I need your help. Expert baristas reading this in South Korea, Australia, New Zealand, Japan, Russia, China, Taiwan, Canada or the United States — you folks who are truly dialed in — test out what I have claimed on your bar. If you think it’s true, raise your voices like we all did for PID espresso machines. Let manufacturers know there is a true artisan market worldwide, waiting for the perfect espresso grinder

The views expressed here are solely those of the author/s and do not necessarily represent the views of the Daily Coffee News, its management or its affiliates.

David Schomer

David Schomer is the co-owner and founder of Seattle’s Espresso Vivace.

He is the author of "ESPRESSO COFFEE: Professional Techniques” (1995) and recently published the 2022 edition of “ESPRESSO PERFECTION”. He created the video Caffe Latte Art in 1995, and an online seminar entitled "ESPRESSO PERFECTION, a companion to his latest book.

David’s temperature research with La Marzocco led to the adoption of PID controls throughout the espresso machine industry.

David has trained hundreds of baristi over his 35 year career at Vivace.

Comment

8 Comments

Comments are closed.

Oh David, there you go again, knocking about in the outback where no one else has tracked….. had it been almost anyone else going on about grinders like this, I’d have clicked BACK t the first paragraph.

But I learned about fourteen years back that when David Schomer is on about something, one oughtn’t pass it by.

I was brand new and VERY wet behind the ears in the world of coffee and decided to attend Coffee Fest in 2005. The morning sessions were fascinating… but there was one time slot I couldn’t find anything that I thought would help me. I’d always scorned those who liked espresso, all of I’d ever had was wretched, so I figured anyone who liked it was nuts or had their taste buds shot. But, nothing else happening, I decided “well, if I’m going to be in the coffee industry it won’t hurt much to learn a couple things about the stuff.

Your approach to the subject blew me away… you had mastered both the art and science of espresso, understood it and could articulate it in a way that opened my eyes and mind. That was the year the first Synesso machines were on the show floor, and in closing you issued a challenge…. git on out there and go find that booth, and see if I don’t know what I’m talking about. So, the gauntlet thrown, I picked it up and walked out and found their booth. For the second time in an hour I was blown away again, when I tried an espresso that was so delicious I HAD to beg for another (still have the cool Synesso branded shot glass they were giving away……). Then the barista did something totally unexoected.. he was using a split portafilter, thus pulling two at once, and had tried the first shot he had given me. He said that one was a bit too acidic, and wanted to adjust the temperature at the group head before pulling another. He did so, handed one to me again, and it WAS noticeably sweeter and smoother. This verified your claim that stable temperature at the group head IS critical. He had changed it one half degree C.

I’m not very failiar with the common espresso grinders in use, other than just seeing them on the counters of shops when I go in. Not up to speed on the differences. I DO now that over half the finely ground coffee in the next shot will have sat there INSIDE the grinder since the last shot had been ground….. back to back grinds, probably not a bog deal. but ten minuts between grinds, as will often happen some places/times of day, OH YES.

A quick look through some of the images you provided with this piece (hat’s off, you ALWAYS illustrate your work, spoken and written, with stunning images) reveal two things that I can think of right off.. first, the exit path for the grounds is all wrong.. huge expanses of flat surface, which, thanks to gravity, really suck… the grounds down onto them, and nothing moves them to where they need to be.

Second, the pieces are metal, it would appear mostly aluminium. That metal in particular is often given to developing a static charge, which encourages those grounds to stay right there on the huge expanses of flat surface. NOT where they need to be. Design the groundcoffee exit path such that gravity will still suck, but do so more effectively beause of a nice steep slope down which to slide those particles. Change to a different material that does not play well with statically charged fine particles. allowing them to quickly fall into the PF.

I strongly suspect that when the first “out there” innovator puts on his thinking cap and redesgns that antique machine we now use and cures the issues you lay out, that one will become rather wealthy…. I am convinced it WILL make the difference you claim it will. . The art and craft of espresso will take another giant leap forward.

Doesn’t Versalab put out a grinder that answers all 5 of your concerns? or, at the very least 4 out of 5 (they say they use a long grind path and a slow rpm, but I don’t know if it’s as slow at 2g/sec. On that note, I’m not sure if 2g/sec is an absolute target, or just the necessary speed for the size of burrs you are using. The larger the grinding surface, the higher output, no?

As far as auto shut-off and grounds retention, the first problem exacerbates the second. if you pre-portion doses before you drop them into the hopper, you can run the grinder empty and expel more. It’s surprisingly less prep time than people think, and all but the highest volume shops can fit it into their workflow.

Hmmmmm. . . . This time, we are on the same page. Couldn’t agree more.

Something like this?

http://tappe.coffee/portfolio/2046/

Check out Kafetec. I have both their conical and flat and they’re the best I’ve ever used.

Kafatek Monolith, EG-1 by Lyn Webber, HSM by Option-O/Helor. Now there is an Atom Pro by Eureka and Ceado Hero ($6500 lol) that can single dose with a bellows. All of these machines are more in the realm of cupping/lab use or ultra high end coffee. The management of fines is really not addressed with any of these grinders and only the Atom Pro and Hero can really be immediately tamped without a bit of whisking or other finesse. So in a way we are very close to your request if not there if someone added an auto-whisk to a grinder and static fines trap we may be there now :). Maybe it is out there being testing in a garage some where 😉

Static is the problem. Free-flowing grounds will adhere to something whether static dissipative, resistant or grounded. Ion generators may work except for a patent in place though never implemented. Compressing the grounds dissipates the charge, which is why doserless grinders work reasonably well, but the restriction required to do so–and time the dose–results in residual grounds. Our patent spins the grinder in reverse to clear the chamber and unload the burrs and also covers varying the grind speed according to each roast or brew method.

And yes, its in my garage . . . and looking for someone to help me finish it.

I think the Mythos 1 and 2 from Nuova Simonelli are the best for me: Flat burrs almost vertical so no left over grinds between the portions…. slightly heated burrs so the distance between the burrs remains and I can work in changing climate in-or outside on fairs…. The M2 even lets you adjust the RPM to prevent fines at the end and one can adjust the seconds t gets slower at the end of the grind. I never had a grinder that gave me the exact amount I asked for. The M2 even weights the coffee – just don’t clean the forks when it’s on or it tares and starts grinding 😀

So when I grind the same coffee on different grinders, the M1 always produces the best flavors…. just my 2 cents 😉

Thank you for pushing the industry. I have recently purchased an ECM syncronika with flow control, dual boiler PID machine and a CEADO E37S grinder. This is really pushing my ability to tune everything in a get the best shots but the equipment is pretty fantastic – horribly expensive – I have many friends who think the $6000 plus for home espresso is lunacy. If anything I think I should have gone for the CEADO E37SD- that’s the single dosing version. Given the importance of freshness why would you store beans in a non airtight clear container on the grinder?