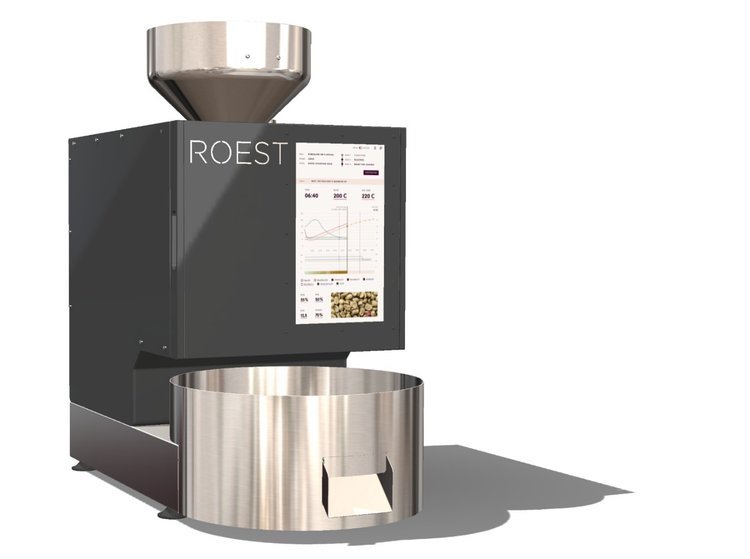

Norwegian coffee roasting equipment maker Roest (formerly Røst) has launched new digital tools for its sample roasting machines.

The company has also announced a capacity upgrade for its forthcoming commercial-size roaster, the P3000, which replaces the P2000 concept introduced last year

.

New Web Portal Features

Earlier this year Roest began shipping S100 Plus and L100 Plus sample roasters with upgraded hardware for its “Web Portal” digital platform, which provides a live graphical view of roasts as they progress, plus storage to the cloud and profile automation.

New to the Roest portal is an inlet temperature sensor, as well as programming and automation for resetting the machine between batches.

Additional new software features include: overlaying graphs for comparing and analyzing roast logs and live roasts; sharing and downloading profiles among the Roest user network; cupping session organization tools; and green coffee inventory management features.

“During the last year, we hired a front end developer to help us create new features we had in mind for the web portal,” Roest Head of Marketing Veronika Galova Bolduc told DCN. “[We also had] a long wish list from our customers who know from first-hand experience what they were missing.”

A Roest L100 sample roaster on display at the 2022 SCA Expo. Daily Coffee News photo by Howard Bryman.

The P3000

Roest has also announced a capacity upgrade to its first machine designed explicitly for commercial production applications. Now known as the P3000, the upcoming roaster will offer a 3-kilogram capacity, as compared to the original 2-kilo concept model known as the P2000.

The machine will be augmented by high-precision sensors and advanced algorithm-based automation capabilities, according to the company, which introduced its first roaster to the world in 2017. The company plans to unveil a final prototype of the P3000 in 2023.

“Our goal with this product is to implement machine learning and to use aggregated data to provide users with smart features,” said Balduc. “To collect reliable data, we use many custom-made sensors that are very fast to respond, much faster than traditional roasters. This helps us to deliver consistent results.”

In addition to the company’s existing automatic first crack detection system, the P3000 will include an integrated camera that will collect visual data as roasts progress.

“With the camera we can track the color and measure the bean size,” said Balduc. “We can also track the development of the bean size during the roasting, especially during the first crack. For example, you can put Kenya AA beans into the roaster, input all the information about the bean you are about to roast, and the machine will tell you, ‘This is not AA; it is AB,’ and [provide] a suggested roasting profile.”

Roest has also been busy testing an electric afterburner for smoke mitigation, as well as a 100-kilo-capacity green coffee storage unit that can weigh and automatically dispense. Both of these will be designed for use with the P3000. Balduc said the company hopes to have a prototype of the P3000 on display at the SCA Expo in Portland, Oregon, in April.

Does your coffee business have news to share? Let DCN’s editors know here.

Howard Bryman

Howard Bryman is the associate editor of Daily Coffee News by Roast Magazine. He is based in Portland, Oregon.

Comment