With a friendship that began in the Texas coffee, Jason Farrar and Ryan Fisher packed their respective bags and moved to Denver in 2013 with a simple shared goal: Launch a roasting/retail brand and make it really, really good. The result is Commonwealth Coffee Roasters, which officially began roasting last Fall.

The brand has slowly been building through wholesale relationships, a mobile cart and, most recently, an amazingly detailed new logo and bagged coffee packaging. We were dying to ask Fisher and Farrar about the packaging, but of course Commonwealth Coffee Roasters is much more than a pretty face:

How did you guys connect and what was the impetus for Commonwealth Coffee Roasters?

Ryan: Jason and I met in Dallas, TX where I owned a cafe called Oak Lawn Coffee. Jason was the head roaster for Oak Cliff Coffee, where we bought most of our coffee from. After about a year of knowing each other, Jason mentioned wanting to start a roasting company in Denver at some point. We soon began talking and planning a joint venture that would become Commonwealth Coffee Roasters nearly a year later. Our goal is to be a roaster/retailer; we just haven’t opened a cafe yet.

What does your roastery look like? Any public elements?

Ryan: Our roasting space is still pretty humble. We roast in a 95 year old building that needs a bit of love. It works for us right now as we come up to the end of our first year in business. Our roaster is a Diedrich IR3, but we are in the process of upsizing, most likely to a Diedrich IR12 or something around that size.

We are also in the final stages of building out a small espresso bar at the front of our roastery. We will have a Steampunk Mod 2.1 and Bosco 2 group lever espresso machine, which we hope to replace with Linea PB not too far in the future. As for grinders, we will use EK43’s for both coffee and espresso.

How are you employing your mobile bar?

Ryan: Initially we ran it nearly everyday until about February. We ended up moving our roastery to our current location and didn’t quite have the proper storage and access to the areas we were popping up in. Needless to say, it’s not running daily anymore. Mostly we set it up for special events. This month, we are working with the City of Denver and WayToGo.org to serve free coffee to commuters around the city as a reward for taking public transit. We also have set up at ‘first friday’ events at our friends men’s clothing shop, Berkeley Supply.

Outside of the mobile presence, can you give us any specific details about your retail plans?

Ryan: Currently, we are focused on growing our wholesale business. We have very particular expectations for our future retail spaces, so we are being patient as we explore the options that become available. We would love to be able to open up a flagship storefront/roastery in 2015, but we will have to see.

I ask this question of every roaster, and it’s so loaded that they all hate it. Anyhow, How do you approach each roast, either technically or philosophically?

Jason: Ultimately, like everyone else (at least I hope so) we want to produce the most delicious product we possibly can. For us, what we look for in the cup is the perfect relationship between sweetness, balance, and complexity. This means a lot of cupping, refining, and more cupping, initially and throughout the life of that particular offering. Technically speaking, it’s developing those aromatics like crazy during the Maillard reaction, keeping your airflow open as to not muddle the beautiful things that have just come about via those crazy chemical reactions, and making sure not to take caramelization too far so as to not diminish the sweetness of the coffee. On top of all this, a vital aspect to how we roast is consistency. We strive to provide the most consistent product we can to the best of our abilities. There’s no place for changing cup profiles from week to week; we owe it to our clients to ensure that the product they get is the same that they got the week before and will get the next.

What are some of the biggest technical lessons you’ve learned thus far in your roasting career?

Jason: I think the most important thing I’ve learned thus far in my career is to know your equipment and your product inside and out. Doing your best to understand the relationships between any given green coffee you have to the heat you’re applying to it and how that ultimately affects and shapes your end product. This means, density, processing, how your roaster reacts if the ambient temperature in the room is cooler or hotter than it was the day prior, if there are changes in humidity, etc. There are so many factors that can throw a roaster off if he or she isn’t aware or understanding of how they may effect the craft. Along with this, tracking everything and creating systems that will enable you to successfully produce a quality product over and over again.

For me, a beautiful cup of coffee in some ways sets the tone for the day. There’s nothing worse than drinking something that’s not super enjoyable before you get on with what you have to do. So to be able to, in a way, be apart of that ritual for some people via our product is incredibly exciting. My hope is that it’s enjoyed deeply, I mean, not even like savored necessarily, but that something so seemingly mundane as a cup of coffee can provide some degree of pleasure is pretty rad. Also, I love our relationship with our wholesale — coffee serves a purpose and in many ways functions as a vehicle to deepen relationships with people in your community. So to be able to provide a product to someone and to help them with their business and support them in that way is why we do what we do. It’s all about the participation within the relationships; that’s what’s exciting about roasting for me. Plus I love all the science!

You have some wholesale relationships well outside Denver or the Colorado border. What is your approach to those kinds of relationships?

Ryan: In the beginning, we relied upon existing relationships we had in the coffee community to develop wholesale relationships, which is why we have so many accounts in Texas. Then we began taking coffee with us everywhere we went and just giving it to people, which has also been really effective for us. We like to let our coffee speak for itself. More recently, we sent out close to a hundred ‘sample packs’ with handwritten notes, which has resulted in our newest accounts in South Carolina and Missouri.

We are proud of what we do, the coffees we roast, and the brand that we are building, so whenever we can, we get our coffee into peoples hands and see what they think.

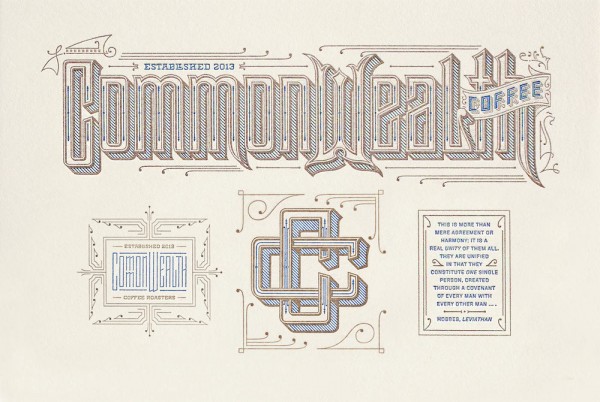

Ok, let’s get to the packaging. It’s amazing. Who did the design work and what were you hoping to communicate?

Kevin Cantrell out of Salt Lake City did all our design work. We wanted to find someone who could take develop a modern and clean Victorian-inspired design. Old Sanborn maps were our inspiration. We wanted flair, but nothing gaudy. We think Kevin hit the nail on the head.

Now that you’re fully settled in Denver and Commonwealth is celebrating its first birthday, how do you see the development of the brand?

We feel that there is still work to be done in terms of establishing our brand. We are very focused on building and maintaining a company that people know they can trust to source and roast amazing coffee. We also are very committed to people. We chose the name Commonwealth to embody our commitment to making everyone successful along the entire chain, from the farmers to our baristas and production team. We believe that we have a moral imperative to treat people well, to honor those we are in business with and to strive to be the best we can.

Nick Brown

Nick Brown is the editor of Daily Coffee News by Roast Magazine.

Comment

2 Comments

Comments are closed.

That’s a gorgeously designed bag. Congratulations guys. Looking forward to stopping by the bar next time I’m in town.

Amazing Coffee.