(Editor’s note: This is a preview of an article that appeared in the September/October 2018 issue of Roast magazine. Click here to read the full article.)

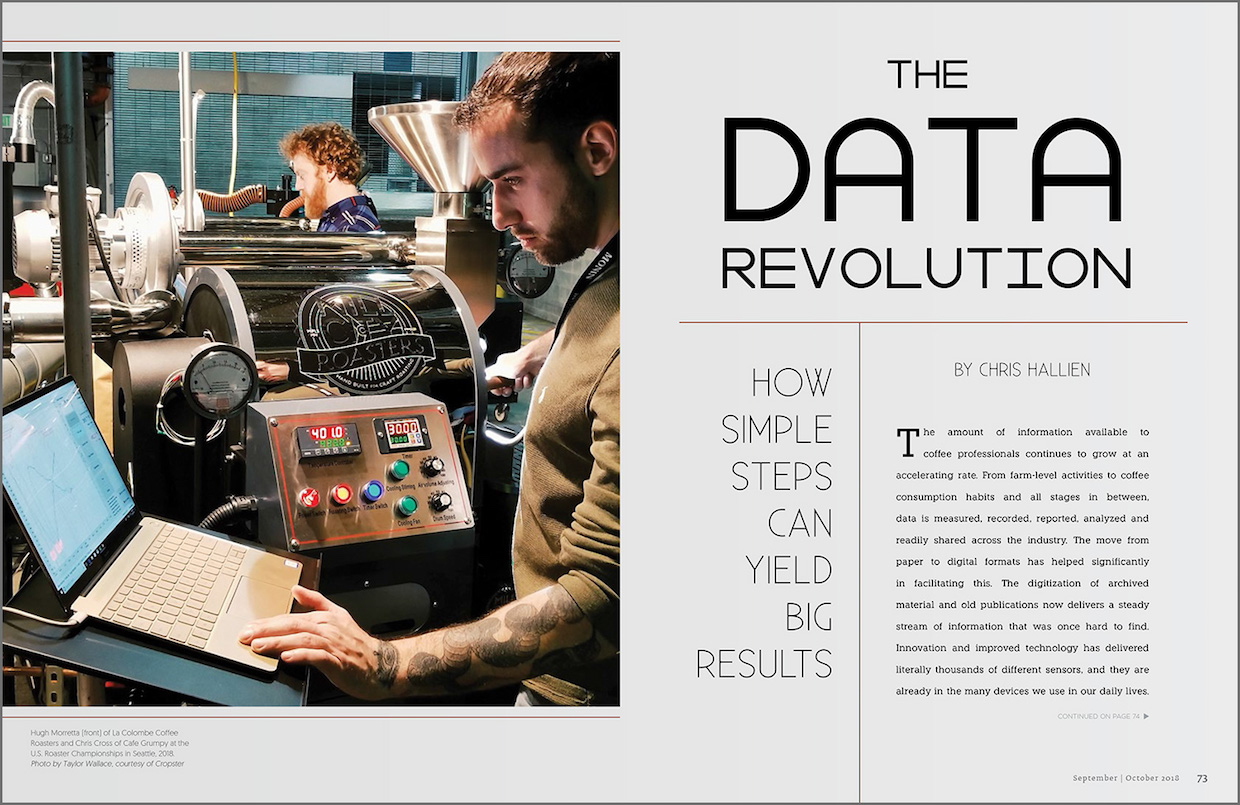

The amount of information available to coffee professionals continues to grow at an accelerating rate. From farm-level activities to coffee consumption habits and all stages in between, data is measured, recorded, reported, analyzed and readily shared across the industry. The move from paper to digital formats has helped significantly in facilitating this. The digitization of archived material and old publications now delivers a steady stream of information that was once hard to find. Innovation and improved technology has delivered literally thousands of different sensors, and they are already in the many devices we use in our daily lives.

At times, it seems like all this information is outpacing our ability to benefit from it. Access to data provides tremendous benefits to a business as a key enabler for making informed decisions. On the other hand, data can create new challenges if it requires too much investment to capture and manage, if analysis is erroneous, or if the data itself is not sound. Identifying information relevant to a business and learning how to analyze it often comes with experience. It also requires constant reconciliation with dynamic business environments, evolving goals and changing products, as well as verification of information that originates from unchecked sources such as social media.

Data collection can help a roaster understand the variables available for manipulation during roasting and the influence each variable has on the roasted coffee. Pictured: Coava Coffee, Portland, Oregon. Photo by Mark Shimahara.

Over the course of 20 years in the coffee industry, I’ve been employed at various capacities across diverse companies. As a result, I’ve worked with products ranging from high-quality green coffee sourced from farmers performing experimentation at the agricultural level to low-grade greens requiring extensive cleaning and sorting on the receiving end; from manually operated roasters to fully automated roasting plants; from the full range of decaffeination methods and soluble processes to seemingly every grinding and packaging technology in existence. On multiple occasions, I believed I had encountered all possible combinations of variables within an equation, only to be introduced to an unexpected one. The commonality in all cases was the need to determine what data was important to capture and how to analyze it in order to make the best decisions about the product or process.

Data Collection and Analysis Basics

Data integrity is an essential aspect of the data collection and analysis process. For coffee professionals, data integrity includes sample information, sampling protocols, sample preparation and analysis as well as verification of methods. Green coffee information is generally provided from the supplier and pertains to lot identification and grade — information such as International Coffee Organization (ICO) marks, certificates of origin and organic certification. Various other details often are available from origins requiring green coffee to be processed through a government agency as criteria for export. Information related to variety, altitude, processing type and other attributes have become increasingly commonplace — all of which reasonably can be assumed to be accurate.

Consistent roasted coffee quality results from consistent green coffee quality and control over the roasting process. Photo by Mark Shimahara.

Several organizations such as ICO, the Specialty Coffee Association (SCA), the National Coffee Association USA (NCA) and the Intercontinental Exchange (ICE) provide guidance in one or more areas around sampling, preparation and evaluation. Other organizations such as AOAC International and ISO serve as sources for analytical testing methods. Often, coffee companies will create their own standard operating procedures (SOPs) by combining information from various sources to fit their individual needs.

SOPs are extremely beneficial to data integrity as they outline the flow of a procedure, where to record output, and the unit of measure to use. Standardization of the units of measure is essential. Within any company, there are often ambiguities: assumptions based on context, for example, such as green coffee weight versus roasted coffee weight; lack of reference scales, such as Celsius versus Fahrenheit or Agtron Gourmet versus Agtron Commercial (or the absence of a scale altogether); or using subjective descriptions such as “medium grind” to refer to a grind size of 750 microns. Agreement on units of measure reduces ambiguities. The use of digital platforms for data management can assist by being formatted to a single standard that defines how to input data.

[Click here to read the full article]

________

Chris Hallien is product manager for Cropster: Roast and Cropster: Coffee Lab. He is a long-standing member of and presenter for the Coffee Roasters Guild and the Specialty Coffee Association, where he serves on the Standards Committee. Hallien is a licensed C grader, a licensed Q grader, a certified sensory scientist and a food scientist.

Comment