(Editor’s note: The following comes from an article by Levi Rogers that appeared in the September/October 2020 issue of Roast Magazine. Click here to read the full article.)

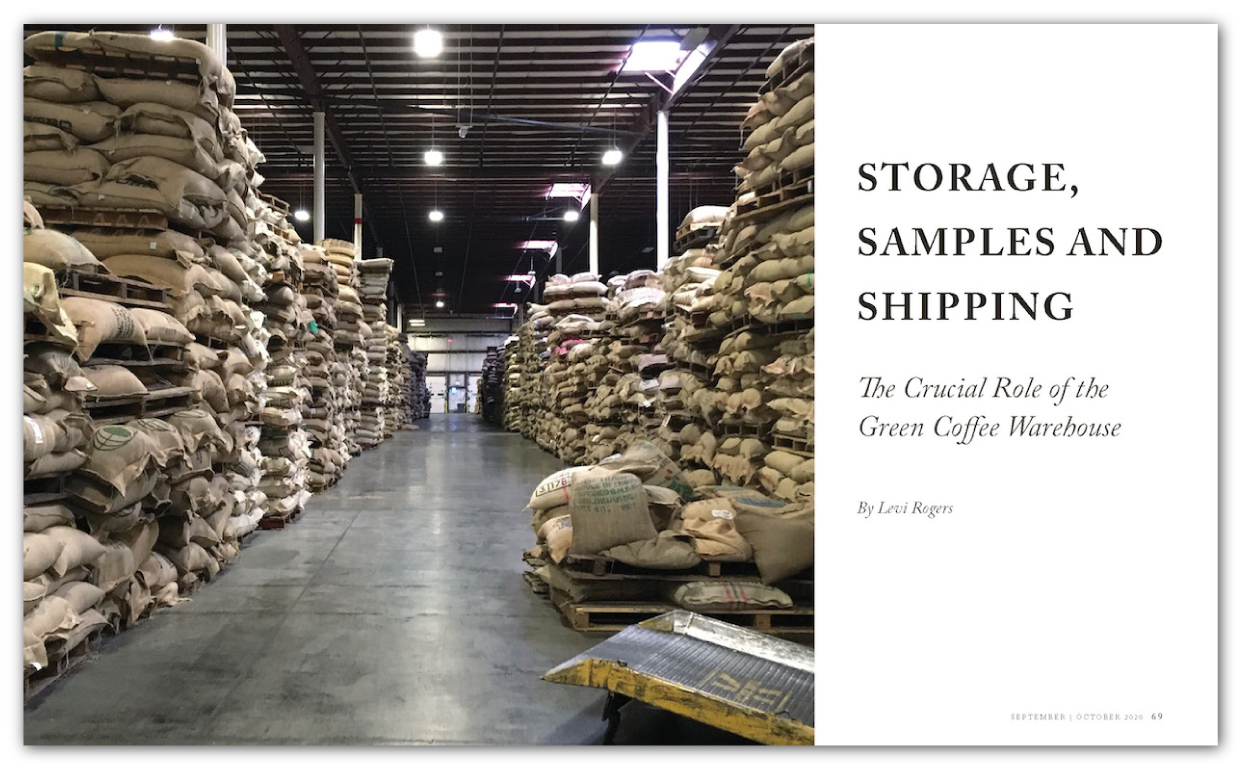

Between the time that green coffee is imported to when it is released to the roaster, there is a key player that is often overlooked when we discuss the coffee supply stream: the independent green coffee warehouse. The warehouse plays a crucial role in ensuring the quality and transparency of the coffee it holds.

Let’s take a closer look at coffee’s journey from the farm to the warehouse, examining the critical stopping points and key terms to know along the way.

Pre-Warehouse Journey

Coffee is shipped in containers on vessels from the location where it is grown and processed. Before this step, someone must transport the product from farms, mills and co-ops to the port of export. Generally, this role belongs to an exporter, but it depends on the contract. Sometimes the broker will need to pay to arrange transport to get the coffee from a truck (or FOT), into a container and then onto a ship. Once the coffee is loaded into a container and then onto a vessel—or “on board”—it becomes known as FOB or free on board. FOB refers to the price paid to the seller of the coffee, usually the exporter. This price is different from the price the exporter paid for the coffee (which could be for coffee in parchment or cherry), but sometimes the exporter is also the farmer or estate—it just depends on the supply chain.

The responsibility, ownership and title of the container is then passed on to the importer by notice of a delivery order (DO); when the coffee has been imported and clears customs and required inspections, a logistics company or the warehouse will collect the container and deliver it to the warehouse. Port security requires that only registered authorized logistics companies are allowed on the docks to collect cargo.

These global destination warehouses are typically located along the coast at well-established seaports (such as the ports of New Jersey, Oakland or Tacoma for the United States; Vancouver or Toronto for Canada; and Grays or Liverpool for the United Kingdom).

The necessary documentation at this point is the bill of lading (BOL). The BOL is a legal and negotiable document, and an original BOL is required to collect cargo from the port as it establishes ownership. The BOL holds all the important information about the coffee, such as the destination warehouse or roasting company, shipping weight, shipping line and International Coffee Organization (ICO) mark. Unique to each parcel of coffee, the ICO mark includes the country code, parcel number, and the code for the exporter or grower. It is extremely important for the owner of the coffee, be it an importer or roaster, to double check all the marks on DOs and invoices to ensure correct information.

A typical “full” coffee container holds 275 (69-kilo) bags of coffee from Central America or approximately 320 (60-kilo) bags of coffee from origins like Brazil and Africa. Interesting fact: Containers often hold more weight than coffee typically ships. Green coffee is usually half the available space. These are the standard lot sizes that the coffee industry considers a full container load because additional net weight over 45,000 pounds would require special equipment for over-the-road trucking and additional weight fees.

[Click here to read the full article]

Comment

1 Comment

Comments are closed.

Why coffee bean shortage happen or loss in the warehouse ? For example deposite 60 bags .so, these bags loss 50 kg or more .why ?can you give solution