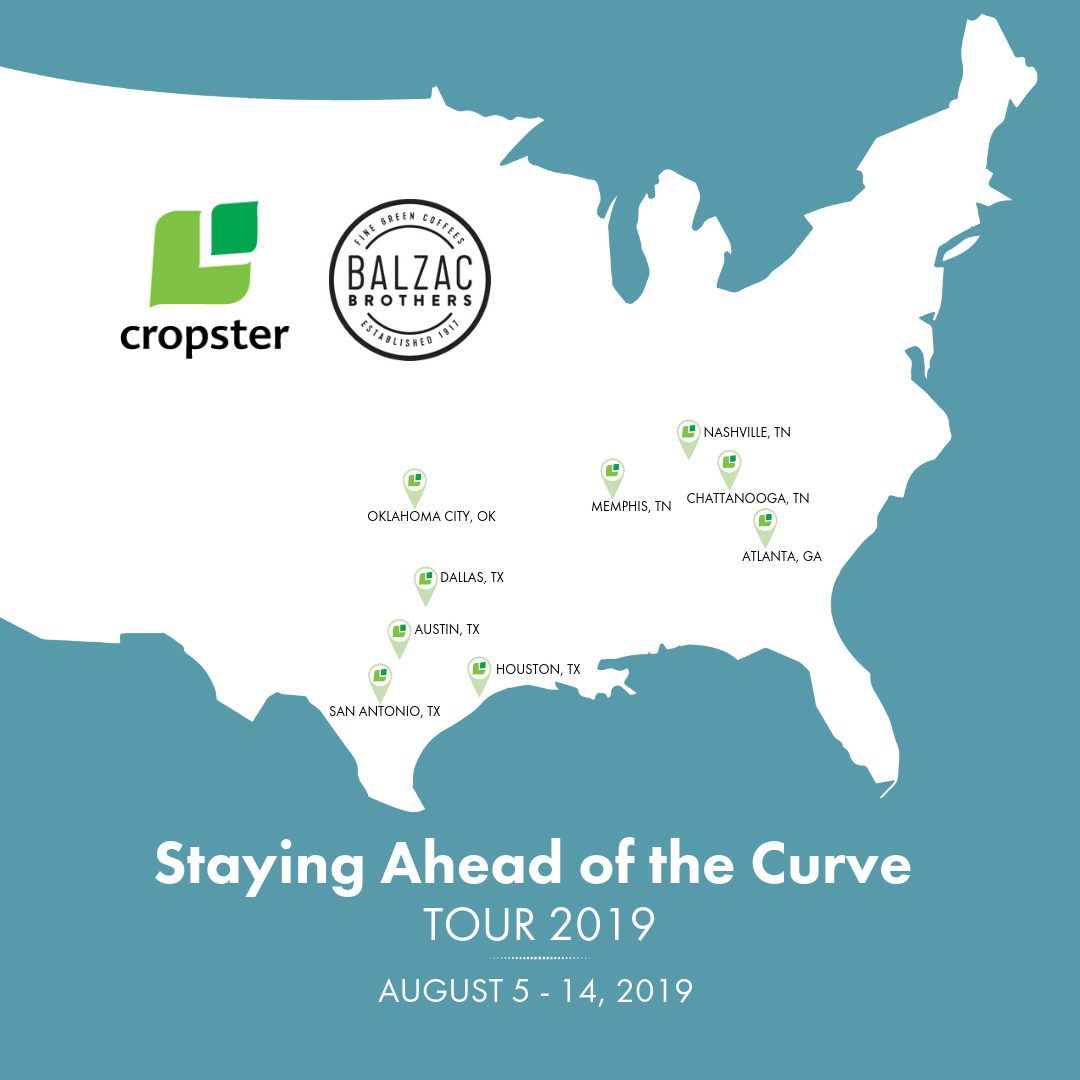

Coffee roasting software provider Cropster and green coffee importer Balzac Brothers have embarked on a tour across the southern United States, starting in Texas and moving through Oklahoma, Tennessee and Georgia. The Staying Ahead of the Curve 2019 tour will include a total of nine workshops over the next two weeks, from Aug. 5-15.

During these workshops, participants will learn about ways to elevate coffee quality and streamline workflows inside the roastery. The goal of the tour is to equip roasters with tools and knowledge to improve operations from top to bottom, including sourcing, roasting, production planning, inventory and cupping. Roasters will also be able to demo Cropster software and speak with directly with importers. In addition to the scheduled workshops, Cropster is meeting with coffee professionals at roasteries in the surrounding areas by request at each stop.

“This partnership came about when [Balzac’s] Erik Stanek and I first met in person at Coffee Fest Indianapolis,” Taylor Wallace, an account manager for Cropster, told Daily Coffee News. “In our brief conversation at the Cropster booth, Erik had brought up the idea of collaboration, seeing as we work with the same people in the specialty coffee industry: coffee roasters. Working with a green coffee importer was something I had been wanting to do for quite some time now and Erik with Balzac Brothers seemed to be just the right person to team up with.”

Here are the Staying Ahead of the Curve 2019 tour stops:

- Houston, Texas: Monday, Aug. 5, at 6:30 p.m., hosted by Blendin Coffee Club

- San Antonio, Texas: Tuesday, Aug. 6, at 6 p.m., hosted by Pulp Coffee Roasters

- Austin, Texas: Wednesday, Aug. 7. at 6 p.m., hosted by Greater Goods Coffee Roasting Co.

- Dallas, Texas: Thursday, Aug. 8 at 6 p.m., hosted by Full City Rooster

- Oklahoma City, Oklahoma: Friday, Aug. 9 at 6 p.m., hosted by Coffee Slingers

- Memphis, Tennessee: Sunday, Aug. 11, at 6 p.m., hosted by French Truck Coffee

- Nashville, Tennessee: Monday, Aug. 12, at 6 p.m., hosted by Barista Parlor Golden Sound

- Chattanooga, Tennessee: Tuesday, Aug. 13 at 6 p.m., hosted by Velo Coffee Roasters

- Atlanta, Georgia: Wednesday, Aug. 14 at 6 p.m., hosted by East Pole Coffee Co.

The workshops are free to attend, but space is limited. Registration will be open until the event is full.

“In our classes along the tour, we will be able to talk about the entire process a coffee roaster goes through to find, source, and create great coffee,” said Wallace. “Erik will be able to provide insights on the entire process of sourcing coffee and I will be able to provide insights on best practices once that coffee enters the roastery all the way until it is being cupped. Our overall goal is to encourage efficiency and consistency in every step of this process.”

Lily Kubota

Lily Kubota is the managing editor and digital content manager for Roast Magazine. She is based in Southern California.

Comment