(Editor’s note: This article originally appeared in the September/October 2017 issue of Roast Magazine. Links have been added for context.)

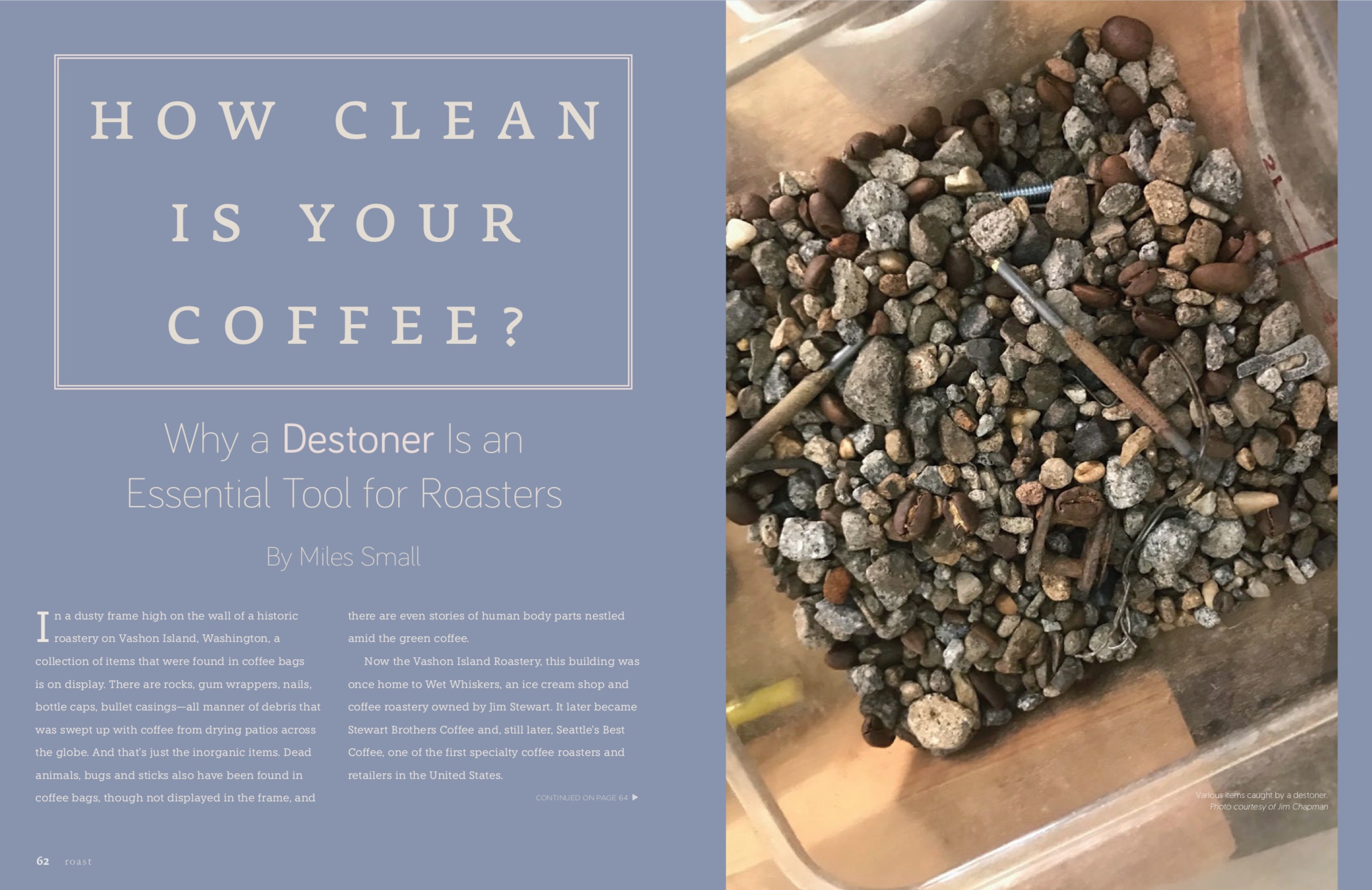

In a dusty frame high on the wall of a historic roastery on Vashon Island, Washington, a collection of items that were found in coffee bags is on display. There are rocks, gum wrappers, nails, bottle caps, bullet casings — all manner of debris that was swept up with coffee from drying patios across the globe. And that’s just the inorganic items. Dead animals, bugs and sticks also have been found in coffee bags, though not displayed in the frame, and there are even stories of human body parts nestled amid the green coffee.

Now the Vashon Island Roastery, this building was once home to Wet Whiskers, an ice cream shop and coffee roastery owned by Jim Stewart. It later became Stewart Brothers Coffee and, still later, Seattle’s Best Coffee, one of the first specialty coffee roasters and retailers in the United States.

In the Beginning

These days, we typically receive green coffee that has passed through several quality inspections during which defects and foreign objects are removed, but that hasn’t always been the case. In the 1970s and ’80s, a small group of intrepid roasters — folks like Stewart, Paul Katzeff, Dean Cycon, Alfred Peet, the Diedrich family, Bill Fishbein, George Howell and others — took it upon themselves to go directly to farms in search of extraordinary coffees. These early specialty roasters had to develop equipment and strategies to clean the coffees themselves.

The first method was simply to visually inspect every bean. They would spread out the coffee and comb through it, looking for foreign material, as well as defects such as blacks, sours, undeveloped and other undesirable beans. Additionally, they took advantage of the physics of coffee. Metals and some stones are magnetic, so they ran the beans past strong magnets to catch and pull out these materials. Coffee beans have predictable densities, so if you vibrate a load of beans on a slanting table, the lighter materials will “float” toward the top. This includes wood, unripe beans, beans with extreme insect damage, and other unwanted organic material. Another screening method was to sieve the green beans through screens sized to let the beans through but catch unwanted material.

In the coffee world, all this is referred to as “triage.”

Still, some items inevitably made it through, regardless of coffee quality, particularly small stones with similar or heavier weights and/or similar sizes to green coffee beans. Roasters solved this problem by taking advantage of the density of coffee and applying existing technology from other industries. They cleaned their roasted coffees pneumatically using just enough vacuum power to lift the beans but leave the rocks behind — and the coffee destoner was born.

A display of objects found in coffee bags at what is now the Vashon Island Roastery. Photo courtesy of Jim Stewart.

Destoners 101

A destoner is an essential part of a professional roasting line. Without a destoner, it is just a matter of time before you can kiss your grinder — or worse, your customer’s grinder — goodbye.

Why? Because stones happen. No matter how carefully your coffee is inspected, stones accidentally get into coffee at the green bean processing plant. That stuff makes it past the processor’s inspection and cleaning systems. It makes it past the grading and dehusking machinery. It makes it past the importer and your green buyer — and it makes it directly into your roaster. Your destoner is the last defense before you accidently drop something hard and unbreakable into your grinder.

But isn’t foreign material a category 1 defect, according to the Specialty Coffee Association (SCA), precluding the coffee from being considered specialty? Technically, yes, but it isn’t as cut and dried as it might appear.

“The SCA specification for washed specialty coffee requires no primary defects, and foreign material is a primary defect,” explains Mike Ebert of Firedancer Coffee Consultants. “This is based on not finding any [foreign material] in a 350-gram representative sample, which means a small amount of coffee was taken out of 10 percent of a lot — for a 250-bag lot, 25 bags were poked and sampled in three locations each, for a total of 350 grams. So no primary defects in a 350-gram sample means the likelihood of there being primaries in the other bags is low, but not impossible. In fact, you can count on it to some degree.”

In today’s specialty coffee world, the most common debris that finds its way into green coffee consists of small stones and small chunks of concrete that are close to the same size and color as a coffee bean. Small bits of wood and insects find their way into the bags as well, but these typically are incinerated during the roast. The bits of stone come from the patios where freshly picked coffee is spread out to dry, then swept up and placed in storage. These vast concrete spaces gradually wear and crumble in the tropical sun and rain, adding little stones to the mix.

How prevalent is this likely to be moving forward? It is hard to say, but processors are taking a much more aggressive stance on cleaning coffee before export (to increase both profits and credibility). Also, the widespread increase in the use of elevated drying beds (suspended plastic-mesh tables that allow for greater air circulation and reduce moisture risks) has reduced the accidental addition of foreign objects, and because the beds are turned by hand instead of raked, the processor has a greater opportunity to inspect the coffee visually during drying.

Although specialty coffee is sorted and inspected at several points on its journey to the roastery, stones and other foreign material inevitably gets mixed in with some of it. Photo by Miles Small.

Destoner equipment comes in a wide variety of styles, but let’s be honest: Destoners are not sexy. You would be a little worried about someone who was deeply in love with his or her destoner. No one brags about uncrating the shiny new destoner they just received along with their ho-hum roaster — nor should they. The roaster is the centerpiece of the operation, but the destoner is a critical tool for delivering quality and customer satisfaction.

Every major roaster manufacturer either builds destoners or has them built for its machines. The designs vary, but they all operate on the same general principles. Destoners have a large tub into which the roasted coffee from the cooling bin is dumped. Usually this is done using the roaster’s cooling bin chute, with the receiving tub nestled against the cooling bin.

The roasted coffee then is drawn from the bottom of the tub using pneumatics — in other words, it is sucked out of the tub — and emptied into a silo-like container. This container typically has a slide gate at the bottom through which the cleaned coffee can be emptied. From there, the coffee goes to the grinder or the packaging line and then to the customer.

Some items have a “specific gravity” that is lower than others, so during the pneumatic phase, the lighter coffee floats up into the silo, and the stones end their journey of thousands of miles in a rattling drop into the destoner’s catch-box. The destoner is the last chance a roaster has to ensure clean, trouble-free coffee. This means the destoner is the last place in the roasting line where you can reduce the risk of seriously messing up a customer’s day.

What to Look For

Here is a rundown of some destoners currently available:

Diedrich Roasters produces a straightforward pneumatic destoner that lifts to a silo, with magnets in the receiving tub that catch most of the metals and metal ore stones. The silo can be elevated to facilitate different methods of packing and storage. One element that distinguishes the Diedrich destoner is the widening arc of the duct that carries the beans to the silo through a downward curving bell shape. This slows the beans as they enter the silo to reduce damage to the coffee.

Giesen and Probat destoners are remarkably similar in appearance and function. They are single-phase electric (standard electrical wiring) and pneumatic, with European and North American electrical supplies. The primary distinction between the two is that the Probat destoner has adjustable feet and the Giesen has casters.

Loring Coffee Roasters makes a stainless steel destoner that operates pneumatically, with the ability to adjust the vacuum for differences in bean density and size. Additionally, there is a side cyclone that functions as a dust collector. This product is designed for the company’s 35- and 70-kilo machines. Loring also puts magnets in their bean carts to catch metals and metal-bearing stones.

The design and appearance of these companies’ destoners vary depending on the size of the roaster. Generally speaking, they all look and work the same; however, for Diedrich and Probat roasters, the destoners for 70-kilo and larger roasters are dramatically different and are integrated into the system control network. The roaster/operator runs all functions of the roast from a central console, including siloing, blending, loading, roasting, destoning, grinding and packaging. These destoners are much more complex in order to handle the rigorous use, production demands and volumes, and the varying weights/densities of coffee passing through the system.

When looking for a destoner, focus on simplicity and ruggedness. Of all the elements of a roasting system, the destoner is the piece most likely to be run into by a forklift — make sure it can take a licking.

Everything on a roaster generally works on a four- to five- minute rule. A green bean loader should put a full load into the bean funnel in about four to five minutes, the roasted beans in the cooling bin should be fully cooled in about four to five minutes, and your destoner should run a full load in about four to five minutes. The reasoning is pretty simple: An operator working full speed has only about 12 to 15 minutes of roast time to cool the beans, empty the cooling bin into the destoner (which is running), and fill the bean funnel so he or she can start the next roast as soon as the roaster temperature recovers. Make sure your destoner — as well as your loader and cooling system — can keep up, otherwise you will lose production time.

Adjusting the vacuum pressure can be tricky. Check with the engineers at the company from which you are ordering. Ask questions about cycle speed (how long it takes to destone a full load), ease of vacuum adjustment, location of operation controls (they should be within easy reach of the roaster), and operational footprint (the total floor space and height required for the destoner to operate).

The size of the tub should match your work requirements. If you are a one-person show, you might not be able to run your destoner while you’re in the middle of a roast. You might want to load up the tub with a full roast and run the destoner later. Be sure the tub of the destoner will hold a full roast if that is your intent.

Finally, the destoner should be easy to clean, and you should be certain you do so at least once per day of roasting. The stone you caught today may very well decide to sail up into the silo tomorrow.

Except for really big roasting systems, there is no law that says you have to buy your destoner from the same company that built your roaster. Pretty much every destoner on the market will fit and work with any roaster. They are two separate appliances and, although they sit side by side, they don’t have to be a matched set. With that said, they are also very much alike. If you like the construction and engineering of your roaster, chances are the manufacturer’s destoners are built the same way.

When it comes time to operate your destoner, the first and foremost rule is never — never! — put hot beans into it. Nothing makes a roaster look and feel worse than having a fire in his or her destoner silo.

Also, all destoners seem to jam up, even in the best circumstances; make sure you pay close attention to how well the vacuum is emptying the tub.

And while this should go without saying, don’t use the destoner tub as a wastebasket! Don’t roll your eyes — I have seen this myself, especially with guests. It is a good idea to cover the tub when it isn’t in use.

“The most random thing one of our roasters found didn’t come out of the destoner. She was scooping Sumatra and found a small blade. It’s probably for cutting string, but we like to call it the Sumatran shiv.”—Thomas Lussier, Dynamite Roasting Company | Photo courtesy of Dynamite Roasting Company.

Do You Need a Destoner?

The big question, of course, is should you buy one? On a theoretical level, yes you should, but life doesn’t always match theory.

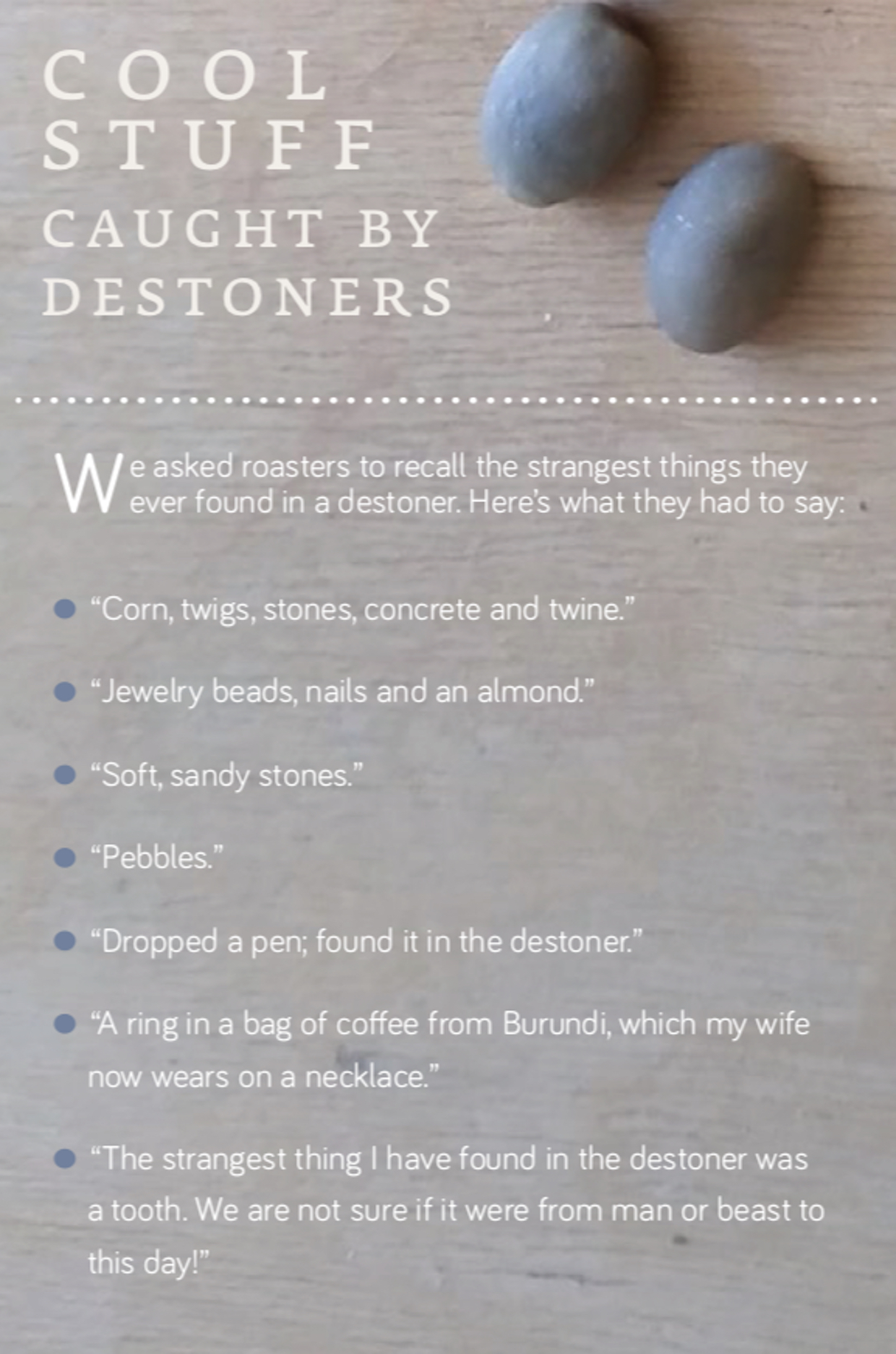

In an informal poll asking roasters about their experiences with destoners, I received more than 100 responses. They can be divided into two distinct groups:

The first group of respondents were roasters who did not own a destoner. These were almost universally small- volume roasters who choose to rely on visual inspection, their suppliers and discipline to ensure quality. The cost, space constraints and perceived lack of need drove their decisions to forego purchasing a destoner.

“Folks who grind at home are our bread and butter,” says Jean Parry of Parry Coffee Roasters [now part of Wake Coffee] in Ambler, Pennsylvania, “but we have a Probat P-12, and a destoner seemed like overkill for that small of a roaster. I have embraced the three to five minutes of cooling time each load as a Zen exercise in scouring the coffee for foreign material.”

Eileen Gentile of Baby Harry Coffee Roaster in Bangor, Pennsylvania, says, “I don’t have a destoner because, after much research, I wasn’t convinced I needed one. In the last year, I have only once found a stone in a bag of Honduran. I was so excited, I saved it! It felt like a prize in a cereal box.”

Renato Correia of Espresso Lab Microroasters in Cape Town, South Africa, adds, “When we started, we did from time to time find the odd piece of concrete or a stone in coffees we purchased from Brazil, Colombia and Costa Rica. As time passed, we stopped coming across any foreign objects anymore. It may be a better screening process at farm level that has contributed to this. We also have reduced the amount of coffees we purchase that are dried on patios, which increases the risk of foreign matter.”

It’s also important to note that, with lighter roasts, the coffee does not lose as much weight (density) as it does in darker roasts. This brings the specific gravity of the coffee much closer to that of stones, making it difficult to tune the vacuum to lift only the coffee. This might make a destoner inappropriate for some companies.

The second group of respondents were generally larger-volume roasters (roasting 2,000 kilograms or more per week). They universally endorsed destoners, primarily based on risk assessment. Destoners help them sleep at night.

“We deliberated extensively on the purchase of a destoner, and every conversation ended in a shrug and some comment about it being the right thing to do,” says Derek Feidell of Gracefully Coffee Roasters in Baltimore. “I cannot imagine Ferrari attempting to justify not using an oil filter just because the required high-quality engine oil does not need it. It serves as layer of protection to the valuable engine. A destoner may not always be needed, but it will serve as a layer of protection to our customers and their valuable grinders.”

Phil Johnson of Pittsburgh’s Commonplace Coffee Co. says, “We use a destoner for all our coffee. The extra time, energy and noise are worth it to save on service calls and replacement burrs. We’ve found that paying a higher price is not a guarantee that your coffee will not have stones. Definitely worth the investment, at the very least for ensuring our customers receive the cleanest product possible.”

And Dave Eldridge of Crimson Cup Coffee & Tea in Columbus, Ohio, notes, “We use destoners. They have produced a couple of keepsake items for us. My personal favorite is the bullet. We also have a large needle used to sew the bags. We will often show these items along with normal pallet nails while giving a tour. The bullet pulls at people’s imagination, and I always enjoy hearing possible explanations of its arrival.”

As the expectations of quality continue to rise across the supply chain, the need for care at the roaster will only become more important. More roasters likely will install optical bean sorters, such as those built by Bühler and Satake, in order to sort for roast color and unseen defects such as quakers. In the meantime, destoners are an essential and easily accessible tool in the ongoing quest for quality and customer satisfaction.

Miles Small

Miles Small has been an active participant in the specialty coffee universe for over 25 years. He currently is a senior consultant with International Coffee Consulting, as well as the owner of Marketing Pax. He was the chief marketing officer at Diedrich Roasters and also the former co-owner of CoffeeTalk Media, publisher of CoffeeTalk Magazine.

Comment

1 Comment

Comments are closed.

Destoner can miss . I use it but my customer still found rock in my coffee bag.

However I think roaster should use it because it’s better than human eyes.