A Chicago-based startup called Zerno is entering the high-end, single-dose prosumer coffee grinder market with its debut machine, the Zerno Z1.

Pre-orders for a limited run of 100 “Launch Edition” machines opened last month and will run until Friday, Sept. 30, with prices starting at $999.

The Z1’s closest counterparts in terms of price and functionality in the growing 64-millimeter flat burr, single-dose grinder category are the lower-end MiiCoffee DF64 (starting at $445), and the RPM-adjustable Lagom P64 grinder by Option-O (starting at $1,475). Another forthcoming entry in the field is the Acaia Orbit grinder (projected to start at $1,350), which promises adjustable RPM and grind-by-weight (GBW) functionality.

Yet the Zerno Z1 offers a number of fresh takes on mechanical design and aesthetics.

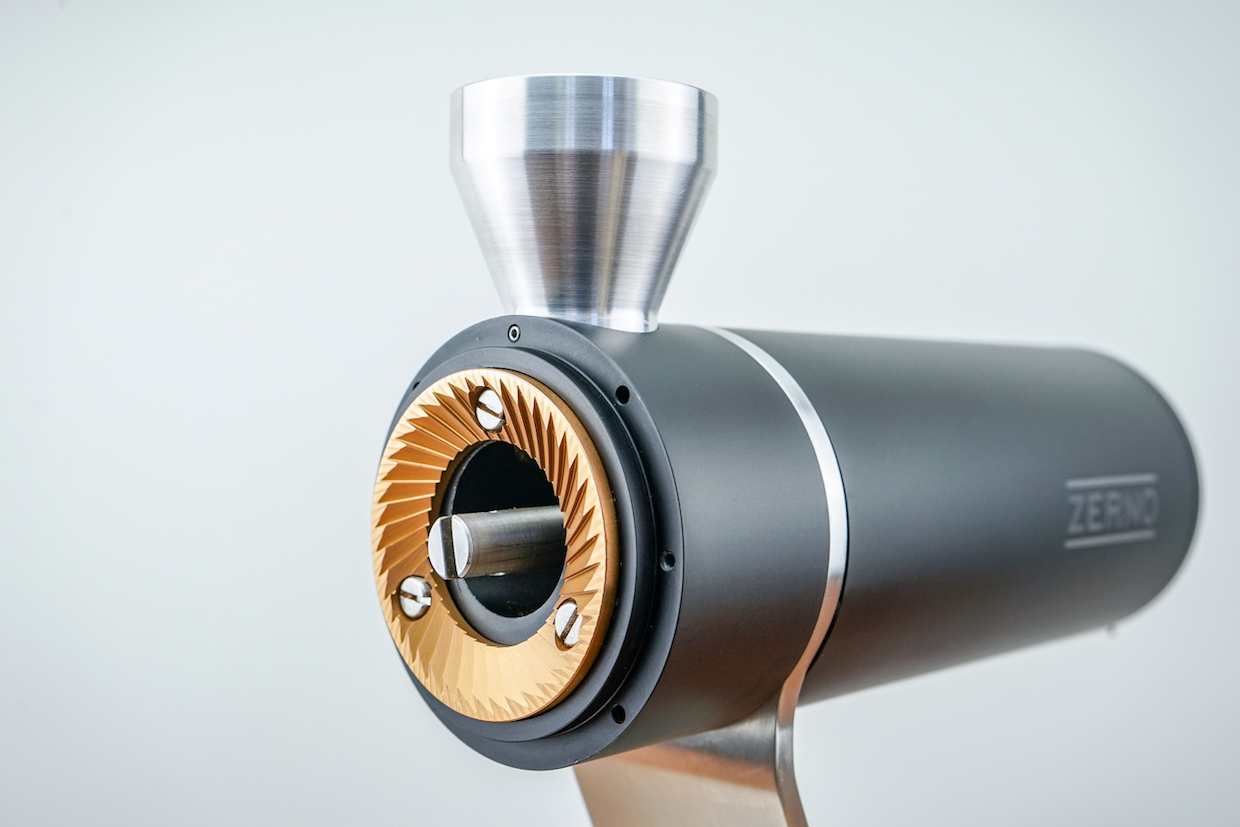

Zerno Co-Founder Vel Genov told DCN that one of the goals guiding the Z1 was to house commercial-grade components in the slimmest possible plastics-free package while maintaining a streamlined aesthetic. The result is the Z1’s purely cylindrical, all-metal body with only two visible screws, necessary to access the insides for cleaning or swapping out burrs.

The screws are on opposite sides of the grinder’s wide stepless adjustment knob, where a customizable wooden front piece is attached magnetically. The entire unit is supported by a minimalist stainless steel stand designed to create the appearance of a grinder floating above the counter.

“We wanted to create a product that’s both beautiful and functional,” Genov told DCN. “The overall diameter of the Z1 is just enough to comfortably fit all of the inner workings — no more, no less. Another big design driver was user customizability. We wanted users to be able to easily customize elements of the Z1 to better match their kitchens and tastes.”

Inside the horizontal column of the Z1’s aluminum body is a high-torque, 300-watt brushed DC motor coupled with a steel gearbox of Zerno’s own design. Together they drive 64-millimeter flat burrs at a fixed speed that the company will continue to tinker with until the upcoming final assembly of its first production run.

“The RPM options that we have tested all produce good results, and I would like to pick the best one,” Genov said, adding that the finished version is certain to land in the 600-800 RPM range. “I would really like to see some empirical evidence to help with the decision, as well.”

“Launch Edition” buyers are given the option of the 64-millimeter multipurpose burrs made by Korean burr-maker SSP or the M33 burrs made by Italian commercial grinder company Mazzer. The latter burr set is typically found in Mazzer Super Jolly professional grinders, in which a 350-watt motor spins them at around 1,600 RPM.

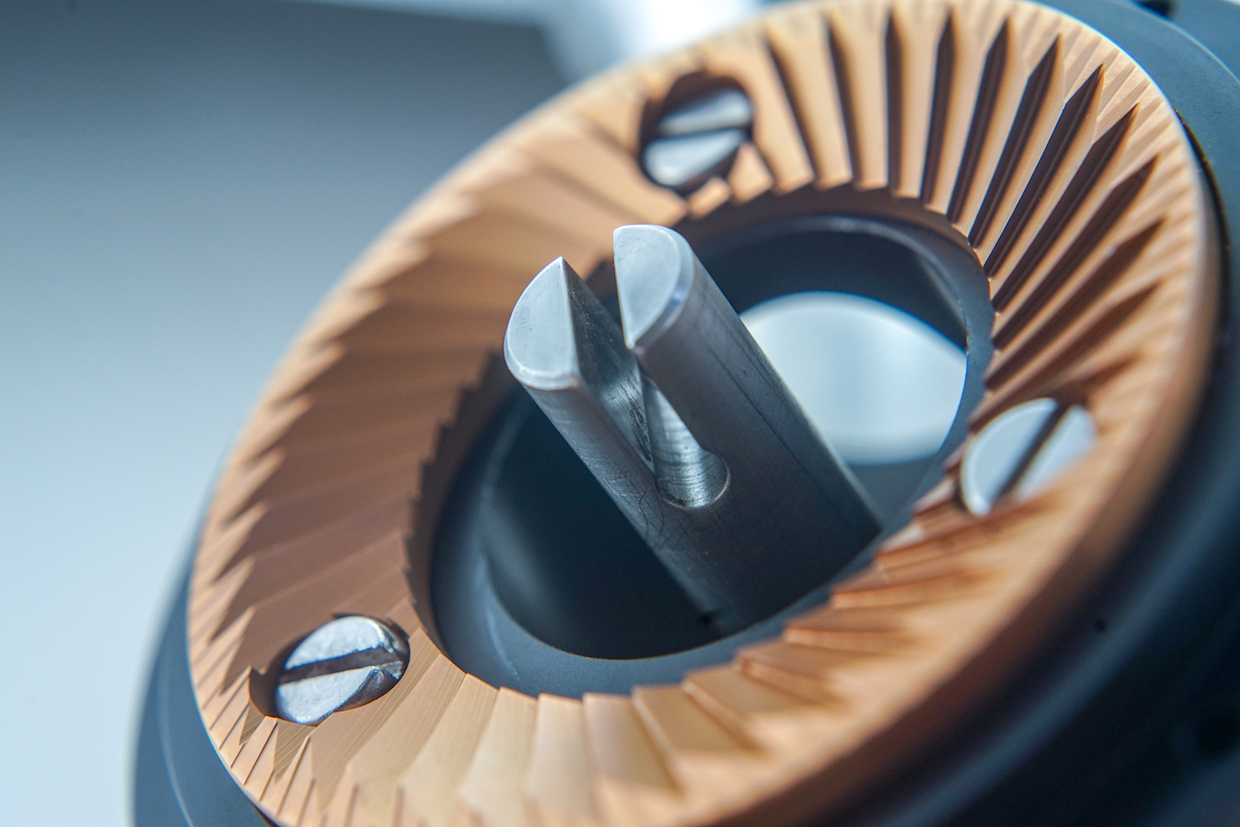

The lower burr speed of the Z1 is enabled by the specific geometry of an innovative anodized aluminum pre-breaker auger that is similar to the pre-breaker found on the much larger commercial Mahlkönig EK43 grinder, and is central to the Z1’s design.

While burr speed can affect the grind in a number of ways, the auger’s pre-breaking action, combined with its snug fit on the drive shaft, contribute to the finished coffee’s particle uniformity, according to the company.

The Z1’s auger slides precisely on and off the drive shaft. Daily Coffee News photo by Howard Bryman.

By crushing the beans against the inner wall of the body as they travel from the hopper towards the burrs, the auger delivers broken bits of bean into the burr chamber for further reduction rather than whole beans that would generate more super-fine particles when they burst upon initial contact with the fast-spinning burr. As the auger and the spinning burr carrier are essentially one piece, the auger’s precision fit over the drive shaft also contributes to the precision of the burr alignment.

“The pre-breaker can slide on the main shaft, but there is no slop,” Genov said. “The pre-breaker is also designed to maximize the contact area with the shaft. This means that the alignment between the main shaft and the burr alignment surface is absolutely critical.”

A 2-ball-bearing system is what keeps the main drive shaft in alignment, while the drive mechanism — including the gearbox, motor and other parts — is housed separately to prevent it from affecting burr alignment.

A Bulgarian-born engineer, Genov built his first robot at the age of 13 before winning multiple robotics competitions in college. Genov’s career has involved product management and software engineering, including work on products from brands such as Adobe and Sony.

Genov and fellow Bulgarian and Zerno Co-Founder Mimo Stoikov have known each other since high school and previously worked together at an Adobe portfolio company. Stoikov has contributed to Zerno R&D while managing supply chain solutions for the Z1. To this point, the duo has funded the company themselves with support from a third investor. Chicago-based creative director Eric Ravenstein rounds out the three-person team behind the Z1.

Parts for the initial 100-unit batch of Z1s are currently in production and heading to Chicago for assembly prior to delivery to customers in the United States before the end of this year.

“Having a limited run sold directly through our website allows us to focus on our early supporters and deliver the best possible experience,” said Genov. “All relationships we’ve established and the partners we’ve brought on board allow us to easily scale production to meet any demand. That being said, we are not in a rush to grow and sell more; we are only in a rush to deliver outstanding quality and support from the very first production run.”

Does your coffee business have news to share? Let DCN’s editors know here.

Howard Bryman

Howard Bryman is the associate editor of Daily Coffee News by Roast Magazine. He is based in Portland, Oregon.

Comment